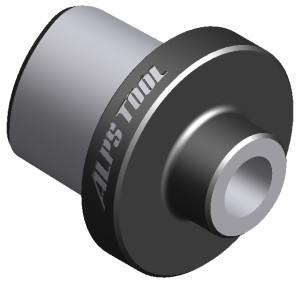

ALPS CAPTO

ALPS CAPTO tooling

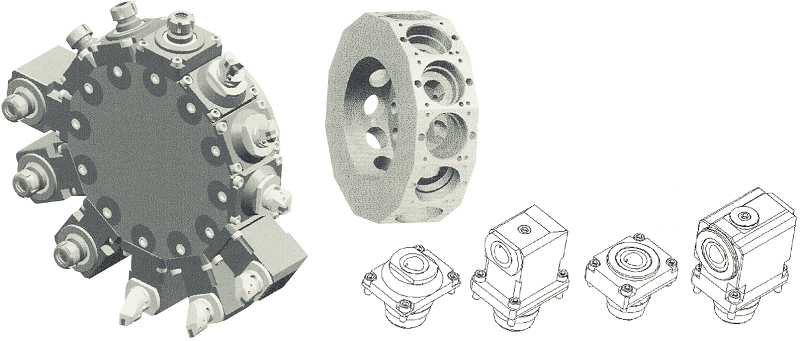

ALPS CAPTO tooling is the most suitable coupling for multi task machine (MTM), CNC lathes, and machining center.

Our various catching systems help realizing high precision and high efficiency.

-

Overview

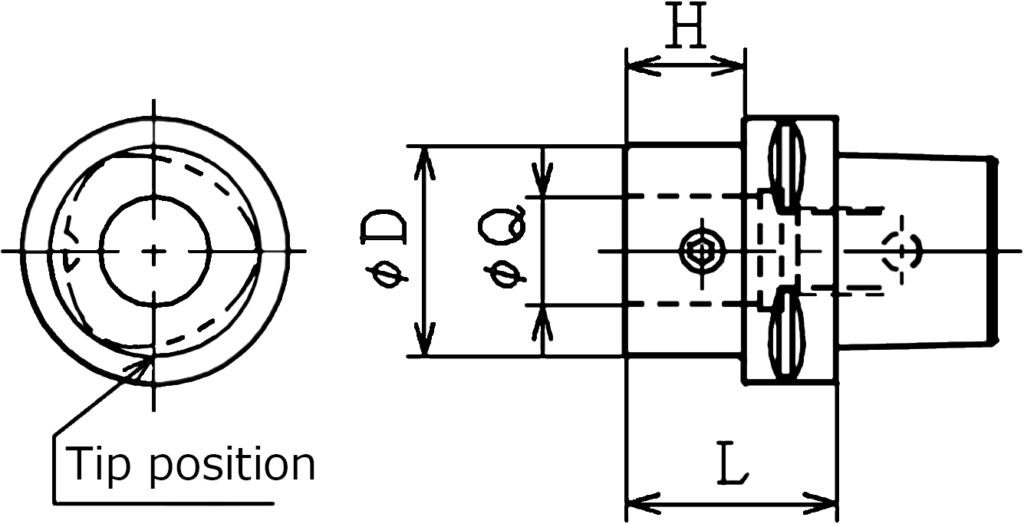

ALPS CAPTO over view

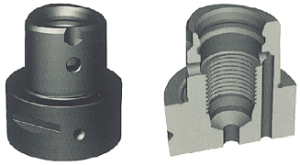

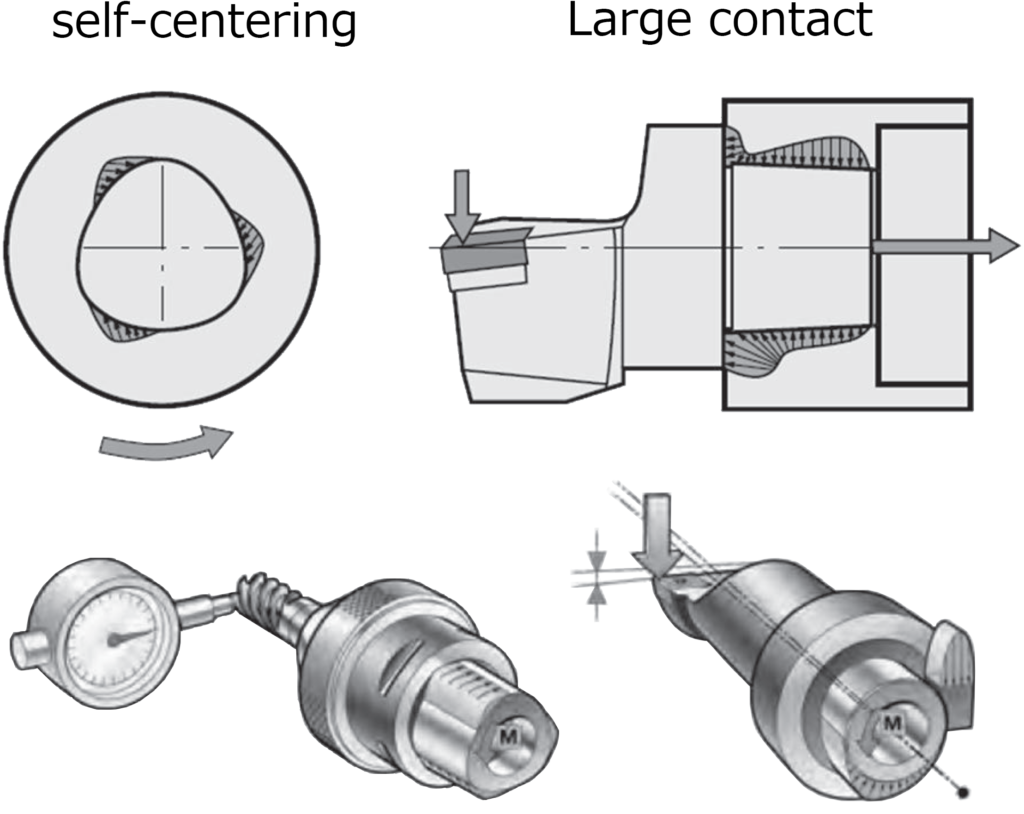

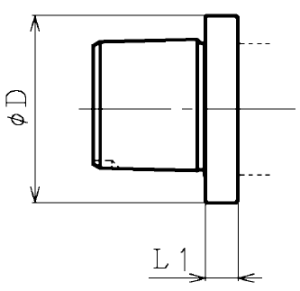

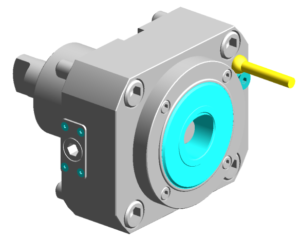

ALPS CAPTO is dihedral constraint type coupling which has polygon formed 1/20 taper.

Quick change system and tool sharing between lathes and machining center realize cost reduction and higher productivity.

High rigidity and precision of ALPS CAPTO is suitable for every machining.

・Dihedral constraint coupling

Enhance rigidity

・keyless coupling

Enhance rigidity and durability by receiving torque on each faces equally.

・High quality coupling

±2㎛, the smallest runout

Size

ALPS CAPTO is available in 5 sizes from C3 to C8.

| Size | Dimensions | Equivalent Shank | |

| C3 | D=32mm | □20 Shank | – |

| C4 | D=40mm | □25 Shank | – |

| C5 | D=50mm | □32 Shank | BT40 |

| C6 | D=63mm | □40 Shank | BT45 |

| C8 | D=80mm | □50 Shank | BT50 |

Clamp unit clamps polygon formed tapered shank with several tons of pressure.

ALPS CAPTO demonstrates its maximum rigidity against bending and twisting.

Gapless polygon form realizes the smallest runout.

Error in height of the blade edge is eliminated owing to coupling without drive key.

Finishing process

Stable machining dimension of work piece.

Rough machining

Prevent position shift and fracture of blade which is caused by pressure comes from deep cutting.

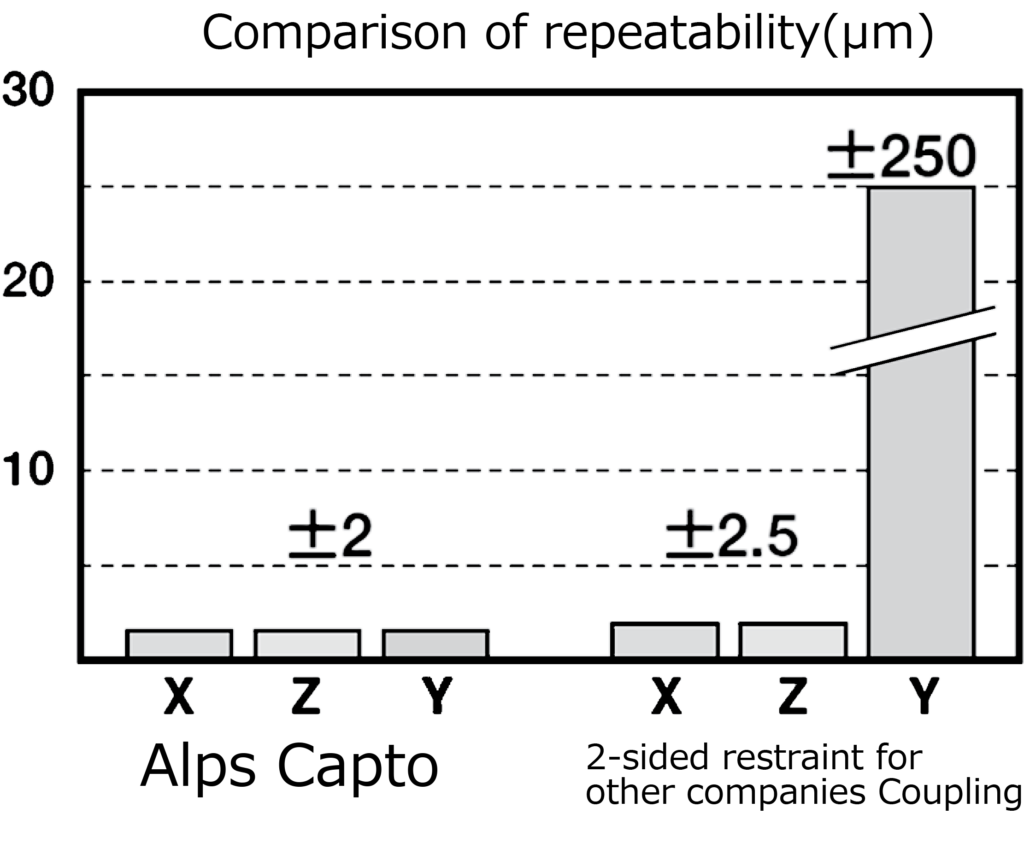

Repeatability

Each X axis , Y axis, and Z axis has repeatability of ±2㎛.

High rigidity

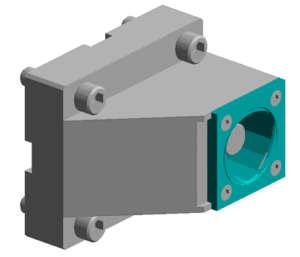

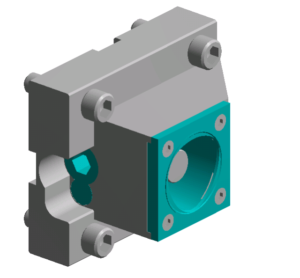

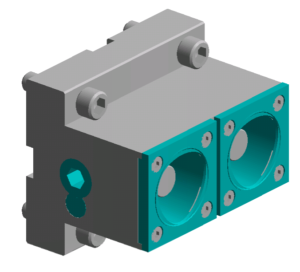

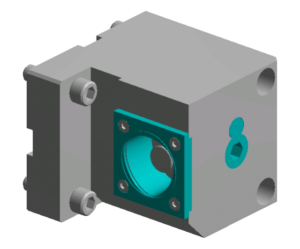

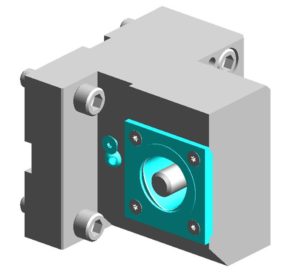

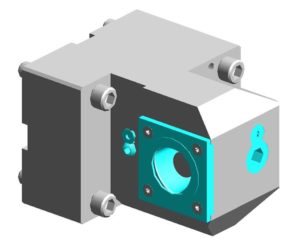

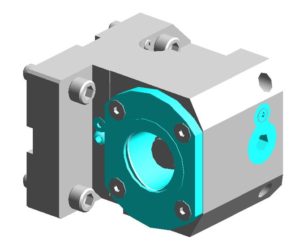

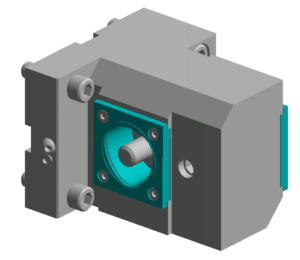

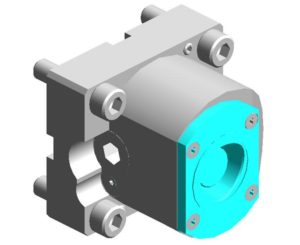

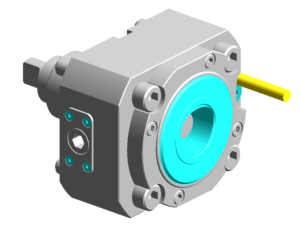

Clamp mechanism

Capto clamp system clamps/ unclamps tooling with the movement of the draw bar and the segment.

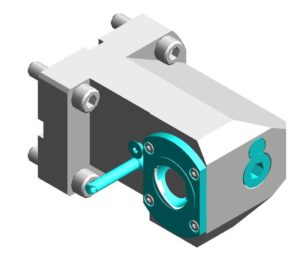

Quick change

Quick change significantly reduces a machine stopping time for tool changing and contributes to cost reduction.

Quick change tooling system for CNC lathes

General turret

| H Size | Capto Size |

| 40 | C3 |

| 50 | C4 |

| 64 | C5 |

| DM Size | Capto |

| 32 | C3 |

| 40 | C4 |

| 50 | C5 |

| 63 | C6 |

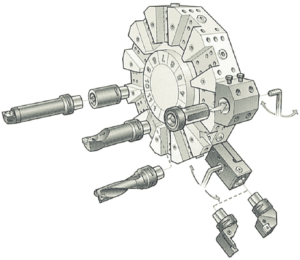

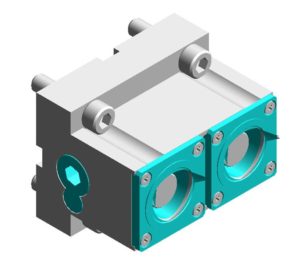

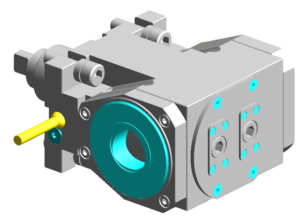

Direct mount type

Quick change tooling system for turning centers.

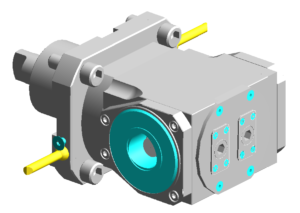

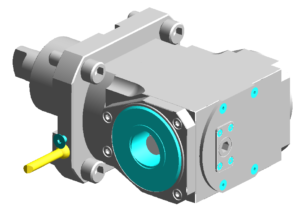

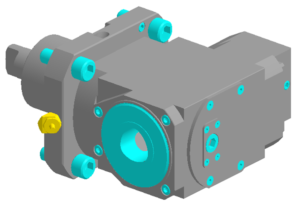

CDI type quick change

Space-saving

Fixed/ rotating tool

Common interface

Shorter holder than VDI

Higher rigidity

Broader machining range

Quick change realized by the capto

Tooling holder

-

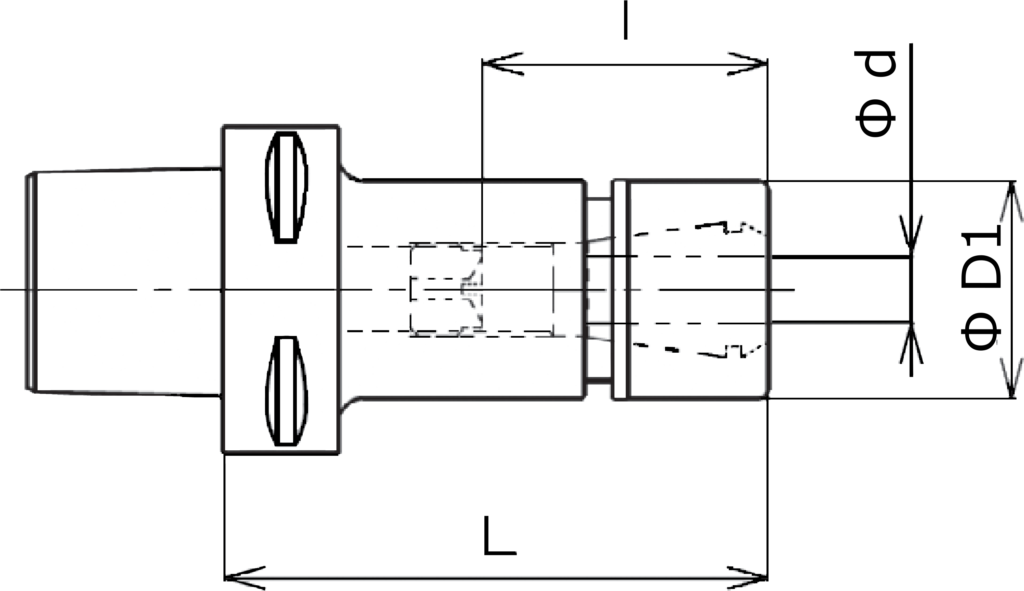

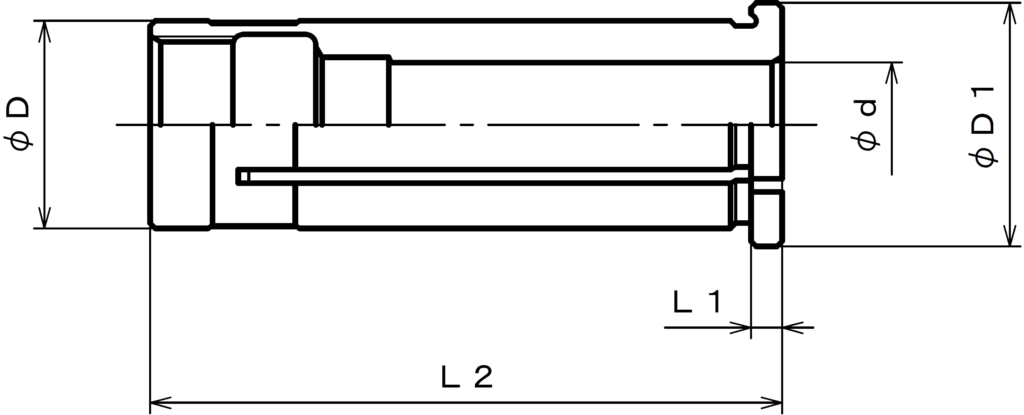

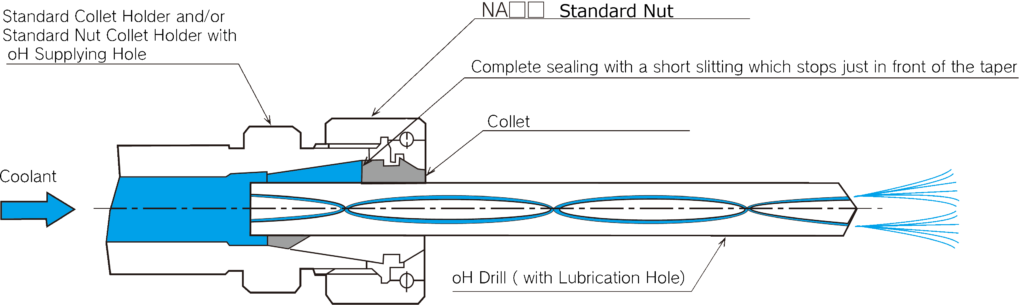

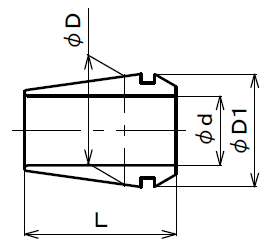

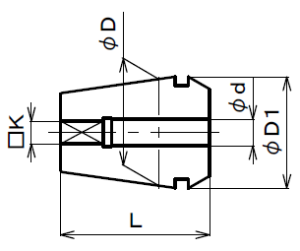

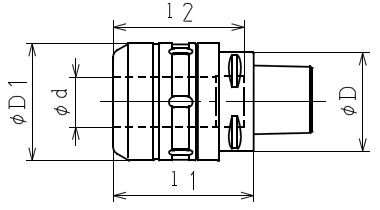

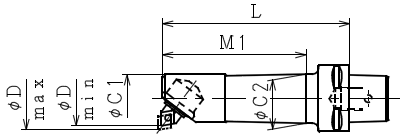

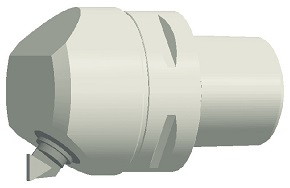

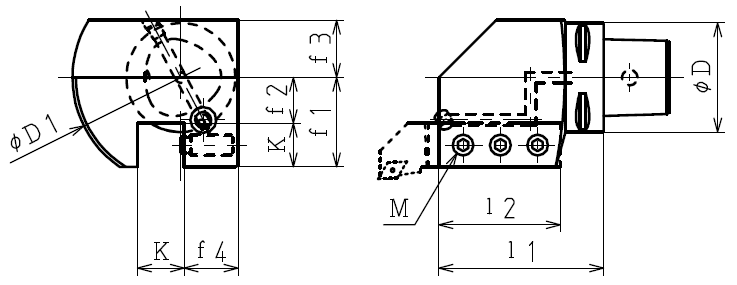

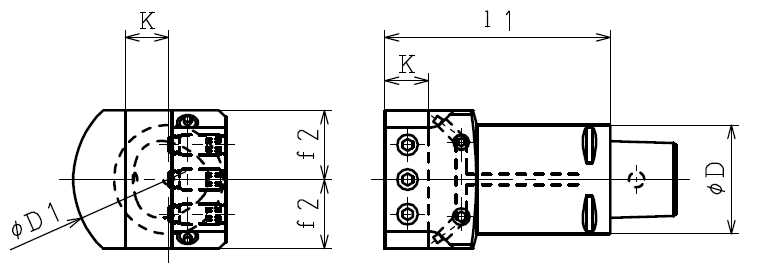

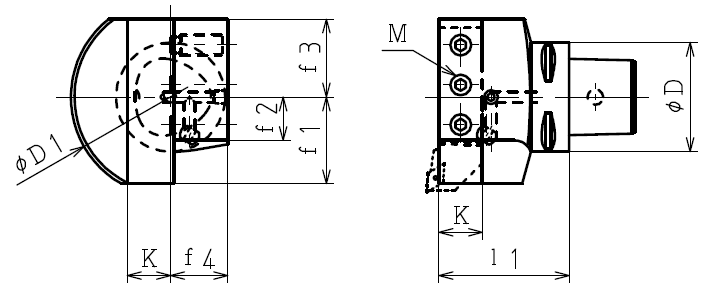

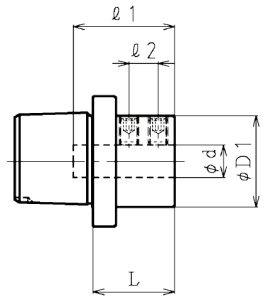

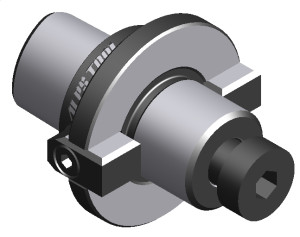

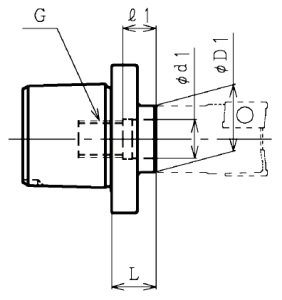

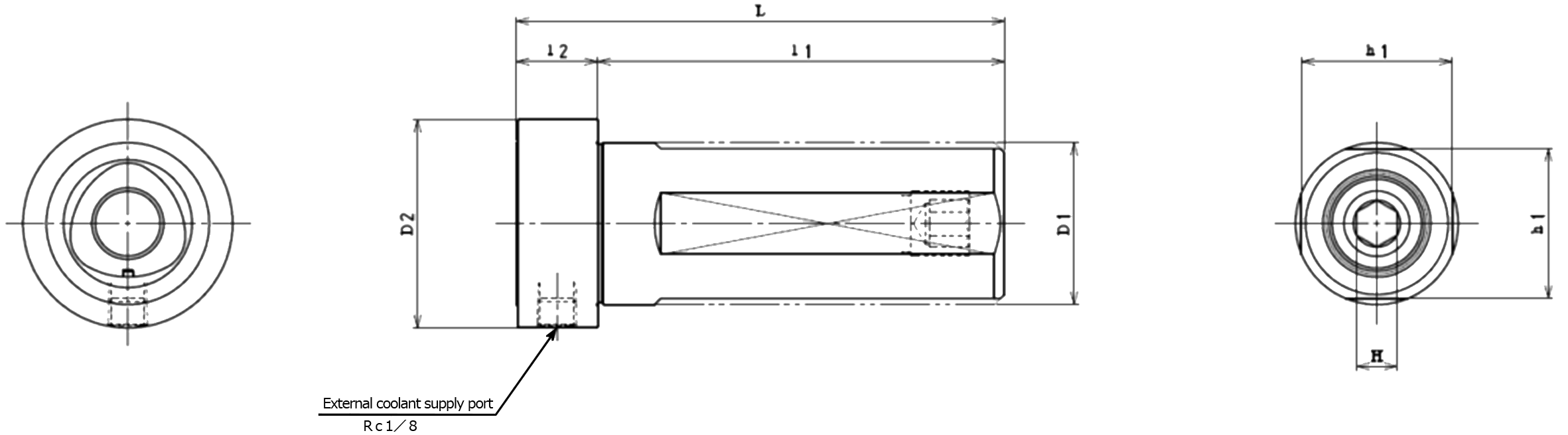

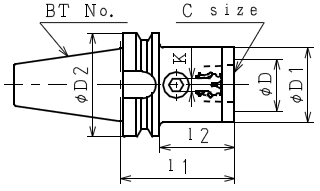

EXH type collet chuck adapter

EXH type collet holder

Suitable for drills, end mills, taps, and reamers.

No need for optional item. become compatible with center through/ side through only by changing collets. (7MPa)

AC5-EXH□□-□□

| CAPTO | Dimension | Adjust Bolt | |||||||||||

| SIZE | CODE | Collet Chuck Code | d | D | D1 | L | l2 | l | w/o Hole | w/ Hole | Nut | Wrench | |

| C5 | AC5-EXH7-60 | AR11-D | AR11OH-D | 0.5~7 | 50 | 23 | 60 | 33 | 42.5※ | ECH7-05 | ECH7OH-05 | NA11FX | XSP23 |

| AC5-EXH7-90 | 90 | 63 | 20~45 | ||||||||||

| AC5-EXH7-105 | 105 | 78 | |||||||||||

| AC5-EXH7-120 | 120 | 93 | |||||||||||

| AC5-EXH10-60 | AR16-D | AR16OH-D | 0.5~10 | 30 | 60 | 35 | 42※ | ECH10-05 | ECH10OH-05 | FA16NX | XSP30 | ||

| AC5-EXH10-90 | 90 | 63 | 30~50 | ||||||||||

| AC5-EXH10-105 | 105 | 78 | |||||||||||

| AC5-EXH10-120 | 120 | 93 | |||||||||||

| AC5-EXH10-135 | 135 | 108 | 30~55 | ||||||||||

| AC5-EXH13-60 | AR20-D | AR20OH-D | 0.5~13 | 35 | 60 | 35 | 45※ | ECH13-05 | ECH13OH-05 | FA20NX | XSP35 | ||

| AC5-ECH13-90 | 90 | 63 | 35~50 | ||||||||||

| AC5-EXH13-105 | 105 | 78 | 40~55 | ||||||||||

| AC5-EXH13-120 | 120 | 93 | 35~65 | ||||||||||

| AC5-EXH13-135 | 135 | 108 | |||||||||||

| AC5-EXH16-60 | AR25-D | AR25OH-D | 0.5~16 | 42 | 60 | 38 | 52※ | ECH16-05 | ECH16OH-05 | NA25FX | XSP42 | ||

| AC5-EXH16-75 | 75 | 51 | 55※ | ||||||||||

| AC5-EXH16-90 | 90 | 66 | 40~55 | ||||||||||

| AC5-EXH16-105 | 105 | 81 | |||||||||||

| AC5-EXH16-120 | 120 | 96 | 40~65 | ||||||||||

| AC5-EXH16-135 | 135 | 111 | |||||||||||

| AC5-EXH20-60 | AR32-D | AR32OH-D | 2.5~20 | 50 | 60 | – | 52※ | ECH20-05 | ECH20OH-05 | NA32FX | XSP50 | ||

| AC5-EXH20-75 | 75 | 67※ | |||||||||||

| AC5-EXH20-90 | 90 | 45~51 | |||||||||||

| AC5-EXH20-105 | 105 | 45~60 | |||||||||||

| AC5-EXH20-120 | 120 | ||||||||||||

| AC5-EXH20-135 | 135 | 40~65 | |||||||||||

AC6-EXH□□-□□

| CAPTO | Dimension | Adjust Bolt | |||||||||||

| SIZE | CODE | Collet Chuck Code | d | D | D1 | L | l2 | l | w/o Hole | w/ Hole | Nut | Wrench | |

| C6 | AC6-EXH7-60 | AR11-D | AR11OH-D | 0.5~7 | 63 | 23 | 60 | 33 | 38.5※ | ECH07-05 | ECH07OH-05 | NA11FX | XSP23 |

| AC6-EXH7-75 | 75 | 48 | 20~35 | ||||||||||

| AC6-EXH7-90 | 90 | 63 | 20~45 | ||||||||||

| AC6-ECH7-105 | 105 | 78 | |||||||||||

| AC6-EXH7-120 | 120 | 93 | |||||||||||

| AC6-EXH7-135 | 135 | 108 | |||||||||||

| AC6-EXH7-165 | 165 | 138 | |||||||||||

| AC6-EXH10-60 | AR16-D | AR16OH-D | 0.5~10 | 30 | 60 | 35 | 41※ | ECH10-05 | ECH10OH-05 | NA16NX | XSP30 | ||

| AC6-EXH10-75 | 75 | 48 | 52.5※ | ||||||||||

| AC6-EXH10-90 | 90 | 63 | 30~50 | ||||||||||

| AC6-EXH10-105 | 105 | 78 | |||||||||||

| AC6-EXH10-120 | 120 | 93 | |||||||||||

| AC6-EXH10-135 | 135 | 108 | 30~55 | ||||||||||

| AC6-EXH10-165 | 165 | 138 | |||||||||||

| AC6-EXH10-200 | 200 | 173 | |||||||||||

| AC6-EXH13-60 | AR20-D | AR20OH-D | 0.5~13 | 35 | 60 | 35 | 41※ | ECH13-05 | ECH13OH-05 | NA20FX | XSP35 | ||

| AC6-EXH13-75 | 75 | 48 | 52※ | ||||||||||

| AC6-EXH13-90 | 90 | 63 | 35~45 | ||||||||||

| AC6-EXH13-105 | 105 | 78 | |||||||||||

| AC6-EXH13-120 | 120 | 93 | 35~55 | ||||||||||

| AC6-EXH13-135 | 135 | 108 | 35~65 | ||||||||||

| AC6-EXH13-165 | 165 | 138 | |||||||||||

| AC6-EXH13-200 | 200 | 173 | |||||||||||

| AC6-EXH16-60 | AR25-D | AR25OH-D | 0.5~16 | 42 | 60 | 37 | 41.5※ | ECH16-05 | ECH16OH-05 | NA25FX | XSP42 | ||

| AC6-EXH16-75 | 75 | 48 | 51※ | ||||||||||

| AC6-EXH16-90 | 90 | 63 | 40~49 | ||||||||||

| AC6-EXH16-105 | 105 | 78 | 40~55 | ||||||||||

| AC6-EXH16-120 | 120 | 93 | |||||||||||

| AC6-EXH16-135 | 135 | 108 | 40~65 | ||||||||||

| AC6-EXH16-165 | 165 | 138 | |||||||||||

| AC6-EXH16-200 | 200 | 173 | |||||||||||

| AC6-EXH20-60 | AR32-D | AR32OH-D | 2.5~20 | 50 | 60 | 36.5 | 50※ | ECH20-05 | ECH20OH-05 | NA32FX | XSP50 | ||

| AC6-EXH20-75 | 75 | 48 | 65.5※ | ||||||||||

| AC6-EXH20-90 | 90 | 63 | 64※ | ||||||||||

| AC6-EXH20-105 | 105 | 78 | 45~55 | ||||||||||

| AC6-EXH20-120 | 120 | 93 | 45~60 | ||||||||||

| AC6-EXH20-135 | 135 | 108 | 45~65 | ||||||||||

| AC6-EXH20-165 | 165 | 138 | |||||||||||

| AC6-EXH20-200 | 200 | 173 | |||||||||||

AC8-ECH□□-□□

| CAPTO | Dimension | Adjust Bolt | |||||||||||

| SIZE | CODE | Collet CODE | d | D | D1 | L | l2 | l | w/o Hole | w/ Hole | Nut | Wrench | |

| C8 | AC8-EXH10-70 | AR16-D | AR16OH-D | 0.5~10 | 80 | 30 | 70 | 37 | 56.5※ | ECH10-05 | ECH10OH-05 | NA16FX | XSP30 |

| AC8-EXH10-90 | 90 | 55 | 30~50 | ||||||||||

| AC8-EXH10-105 | 105 | 70 | |||||||||||

| AC8-EXH10-120 | 120 | 85 | |||||||||||

| AC8-EXH10-135 | 135 | 100 | 30~55 | ||||||||||

| AC8-EXH10-165 | 165 | 130 | |||||||||||

| AC8-EXH13-70 | AR20-D | AR20OH-D | 0.5~13 | 35 | 70 | 37 | 55※ | ECH13-05 | ECH13OH-05 | NA20FX | XSP35 | ||

| AC8-EXH13-90 | 90 | 55 | 35~55 | ||||||||||

| AC8-EXH13-105 | 105 | 70 | |||||||||||

| AC8-EXH13-120 | 120 | 85 | |||||||||||

| AC8-EXH13-135 | 135 | 100 | 35~65 | ||||||||||

| AC8-EXH13-165 | 165 | 130 | |||||||||||

| AC8-EXH13-200 | 200 | 165 | |||||||||||

| AC8-EXH16-70 | AR25-D | AR25OH-D | 0.5~16 | 42 | 70 | 37 | 54※ | ECH16-05 | ECH16OH-05 | NA25FX | XSP42 | ||

| AC8-EXH16-90 | 90 | 55 | 40~53 | ||||||||||

| AC8-EXH16-105 | 105 | 70 | 40~55 | ||||||||||

| AC8-EXH16-120 | 120 | 85 | 40~65 | ||||||||||

| AC8-EXH16-135 | 135 | 100 | |||||||||||

| AC8-EXH16-165 | 165 | 130 | |||||||||||

| AC8-EXH16-200 | 200 | 165 | |||||||||||

| AC8-EXH20-70 | AR32-D | AR32OH-D | 2.5~20 | 50 | 70 | 38 | 53※ | ECH20-05 | ECH20OH-05 | NA32FX | XSP50 | ||

| AC8-EXH20-90 | 90 | 55 | 73※ | ||||||||||

| AC8-EXH20-105 | 105 | 70 | 45~60 | ||||||||||

| AC8-EXH20-120 | 120 | 85 | 45~65 | ||||||||||

| AC8-EXH20-135 | 1356 | 100 | |||||||||||

| AC8-EXH20-165 | 165 | 130 | |||||||||||

| AC8-EXH20-200 | 200 | 165 | |||||||||||

Spanner

XSP□□ , FK-□

| Holder Type | Standard Nut | Wrench | Nut for T-Cutter | Wrench for T-Cutter Nut |

| EXH7 | NA11FX | XSP23 | NA11F | FK-3 |

| EXH10 | NA16FX | XSP30 | NA16F | FK-4 |

| EXH13 | NA20FX | XSP35 | NA20F | FK-5 |

| EXH16 | NA25FX | XSP42 | NA25F | FK-6 |

| EXH20 | NA32FX | XSP50 | NA32F | FK-7 |

Notice

1, Slit through coolant becomes available by using AR collet (AR□□-D)

2, Center through coolant becomes available by using AR coolant collet (AR□□OH-D)

3, Please order a spanner separately.

4, Please replace a standard nut with a NA□□-P type when you use umbrella-shaped tool.

5, Adjust bolt cannot be used on the products marked ※.

-

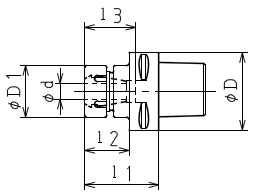

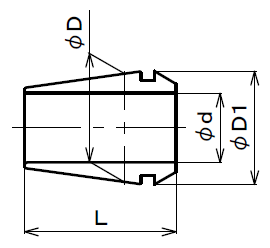

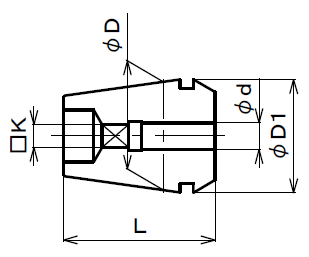

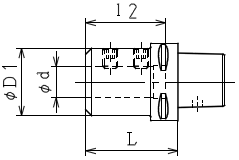

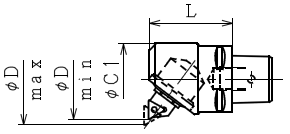

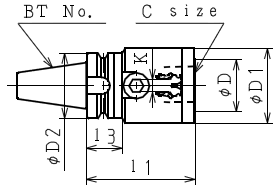

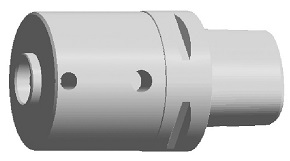

ECH type collet chuck adapter

ECH type collet holder

Suitable for drills, end mills, reamers, and small diameter boring.

No need for optional item. Become compatible with center through/ side through only by changing collets. (7MPa)

AC3-ECH□□-□□

| CAPTO | Dimension | Adjust Bolt | |||||||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | l3 | w/o Hole | w/ Hole | Nut | Wrench | |

| C3 | AC3-ECH10F-35 | AR16-d | AR16OH-d | 1~10 | 32 | 30 | 35 | 21 | 33 | – | – | NA16F | FK-4 |

| AC3-ECH13F-45 | AR20-d | AR20OH-d | 1~13 | 35 | 43 | – | 37 | NA20F | FK-5 | ||||

AC4-ECH□□-□□

| CAPTO | Dimension | Adjust Bolt | |||||||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | l3 | w/o Hole | w/ Hole | Nut | Wrench | |

| C4 | AC4-ECH13F-45 | AR20-d | AR20OH-d | 1~13 | 40 | 35 | 45 | 25 | 37 | – | – | NA20F | FK-5 |

| AC4-ECH16F-50 | AR25-d | AR25OH-d | 1~16 | 42 | 50 | – | 41.5 | NA25F | FK-6 | ||||

| AC4-ECH20F-55 | AR32-d | AR32OH-d | 1~20 | 50 | 55 | 47.5 | NA32F | FK-7 | |||||

AC5-ECH□□-□□

| CAPTO | Dimension | Adjust Bolt | |||||||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | l3 | w/o Hole | w/ Hole | Nut | Wrench | |

| C5 | AC5-ECH7F-60 | AR11-d | AR11OH-d | 0.5~7 | 50 | 23 | 60 | 38 | 22.5 | ECH7-05 | ECH7OH-05 | NA11F | FK-3 |

| AC5-ECH7F-90 | 90 | 68 | |||||||||||

| AC5-ECH10F-60 | AR16-d | AR16OH-d | 1~10 | 30 | 60 | 38 | 33 | – | – | NA16F | FK-4 | ||

| AC5-ECH10F-90 | 90 | 68 | ECH10-05 | ECH10OH-05 | |||||||||

| AC5-ECH13F-60 | AR20-d | AR20OH-d | 1~13 | 60 | 38 | 37 | – | – | NA20F | FK-5 | |||

| AC5-ECH13F-90 | 90 | 68 | ECH13-05 | ECH13OH-05 | |||||||||

| AC5-ECH16F-60 | AR25-d | AR25OH-d | 1~16 | 42 | 60 | 38 | 41.5 | – | – | NA25F | FK-6 | ||

| AC5-ECH16F-90 | 90 | 68 | ECH16-05 | ECH16OH-05 | |||||||||

| AC5-ECH20F-60 | AR32-d | AR32OH-d | 3~20 | 50 | 60 | – | 47.5 | – | – | NA32F | FK-7 | ||

| AC5-ECH20F-90 | 90 | ECH20-05 | ECH20OH-05 | ||||||||||

| AC5-ECH26F-70 | AR40-d | AR40OH-d | 3~26 | 61.5 | 70 | 54.5 | – | – | NA40F | FK-9 | |||

AC6-ECH□□-□□

| CAPTO | Dimension | Adjust Bolt | |||||||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | l3 | w/o Hole | w/ Hole | Nut | Wrench | |

| C6 | AC6-ECH7F-60 | AR11-d | AR11OH-d | 0.5~7 | 63 | 23 | 60 | 36 | 22.5 | ECH7-05 | ECH7OH-05 | NA11F | FK-3 |

| AC6-ECH7F-90 | 90 | 66 | |||||||||||

| AC6-ECH10F-60 | AR16-d | AR16OH-d | 1~10 | 30 | 60 | 36 | 33 | – | – | NA16F | FK-4 | ||

| AC6-ECH10F-90 | 90 | 66 | ECH10-05 | ECH10OH-05 | |||||||||

| AC6-ECH10F-120 | 120 | 96 | |||||||||||

| AC6-ECH13F-60 | AR20-d | AR20OH-d | 1~13 | 35 | 60 | 36 | 37 | – | – | NA20F | FK-5 | ||

| AC6-ECH13F-90 | 90 | 66 | ECH13-05 | ECH13OH-05 | |||||||||

| AC6-ECH13F-120 | 120 | 96 | |||||||||||

| AC6-ECH16F-60 | AR25-d | AR25OH-d | 1~16 | 42 | 60 | 36 | 41.5 | – | – | NA25F | FK-6 | ||

| AC6-ECH16F-90 | 90 | 66 | ECH16-05 | ECH16OH-05 | |||||||||

| AC6-ECH16F-120 | 120 | 96 | |||||||||||

| AC6-ECH20F-60 | AR32-d | AR32OH-d | 3~20 | 50 | 60 | 36 | 47.5 | – | – | NA32F | FK-7 | ||

| AC6-ECH20F-90 | 90 | 66 | ECH20-05 | ECH20OH-05 | |||||||||

| AC6-ECH26F-70 | AR40-d | AR40OH-d | 3~26 | 61.5 | 70 | 46 | 54.5 | – | – | NA40F | FK-9 | ||

AC8-ECH□□-□□

| CAPTO | Dimension | Adjust Bolt | |||||||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | l3 | w/o Hole | w/ Hole | Nut | Wrench | |

| C8 | AC8-ECH107F-70 | AR16-d | AR16OH-d | 1~10 | 80 | 30 | 70 | 38 | 33 | ECH10-05 | ECH10OH-05 | NA16F | FK-4 |

| AC8-ECH10F-100 | 100 | 68 | |||||||||||

| AC8-ECH13F-70 | AR20-d | AR20OH-d | 1~13 | 35 | 70 | 38 | 37 | ECH13-05 | ECH13OH-05 | NA20F | FK-5 | ||

| AC8-ECH13F-100 | 100 | 68 | |||||||||||

| AC8-ECH16F-70 | AR25-d | AR25OH-d | 1~16 | 42 | 70 | 38 | 41.5 | – | – | NA25F | FK-6 | ||

| AC8-ECH16F-100 | 100 | 68 | ECH16-05 | ECH16OH-05 | |||||||||

| AC8-ECH20F-70 | AR32-d | AR32OH-d | 3~20 | 50 | 70 | 38 | 47.5 | – | – | NA32F | FK-7 | ||

| AC8-ECH20F-100 | 100 | 68 | ECH20-05 | ECH20OH-05 | |||||||||

| AC8-ECH26F-70 | AR40-d | AR40OH-d | 3~26 | 61.5 | 70 | 38 | 54.5 | – | – | NA40F | FK-9 | ||

Spanner

Notice

1, Slit through coolant becomes available by using AR collet (AR□□-d)

2, Center through coolant becomes available by using AR coolant collet (AR□□OH-d)

3, Please order a spanner separately.

-

Collet

Straight collet

This is a collet with adjust bolt used in combination with TR/ T type milling chuck.

This is suitable for gripping small diameter straight shank. Center through is not available when ASS□□-D1 is attached to TR/ R type.

| Code | Φd | ΦD | L2 | D1 |

| AS16-D | 6,8,10,12 | 16 | 48 | 20.0 |

| AS20-D | 6,8,10,12,16 | 20 | 61 | 23.5 |

| AS25-D | 6,8,10,12,16,20 | 25 | 63 | 28.5 |

| AS32-D | 6,8,10,12,16,20,25 | 32 | 70 | 37.0 |

| AS42-D | 6,8,10,12,16,20,25,32 | 42 | 78 | 47.0 |

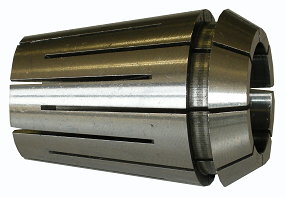

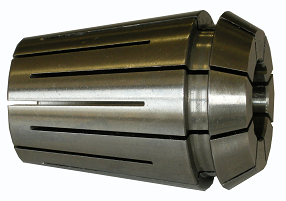

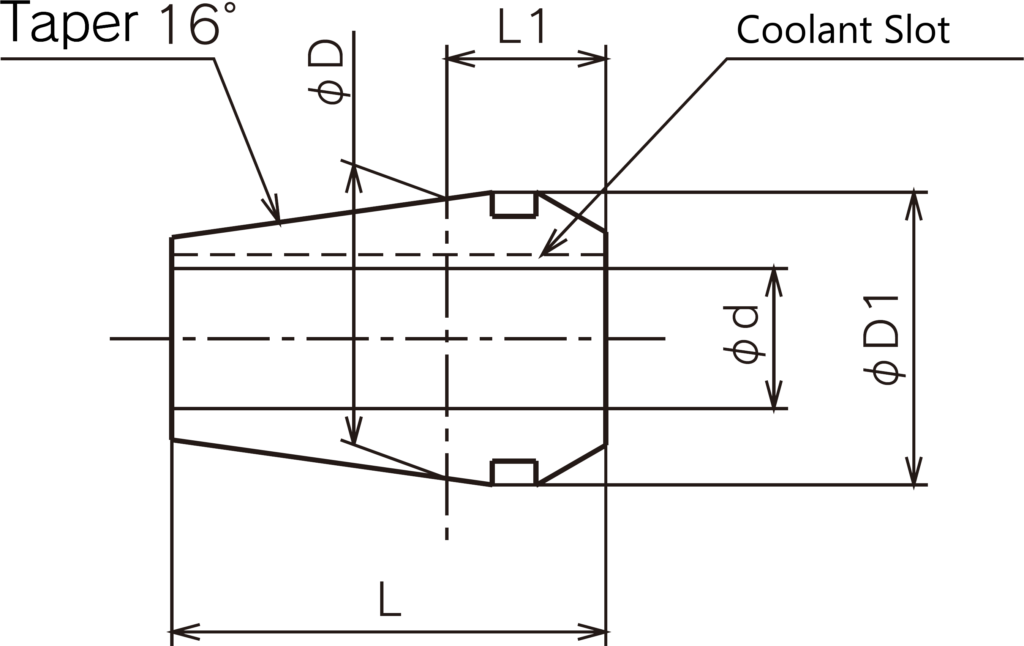

AR collet

This is a handy multi collet with 1 mm of gripping space.

16°tapered collet chuck conforming to DIN6499/ ISG15488

Please refer to ALPS NICE MLL SERIES for more information.

AR□□-D

| Code | Φd | Clamping Range | ΦD | L |

| AR11-D | 1~7 | 0.5 | 11 | 18 |

| AR16-D | 1~10 | 0.5~1.0 | 16 | 27 |

| AR20-D | 1~13 (14) | 20 | 31 | |

| AR25-D | 1~16 | 25 | 35 | |

| AR32-D | 3~20 | 32 | 40 | |

| AR40-D | 4~26 | 1 | 40 | 46 |

Notice

1, The collet can grip tool whose diameter is smaller than that written on φd column.

Example, In order to grip 6.7 mm drill, collet whose maximum grip range is 7 mm (AR11-7, AR16-7, and etc.) is suitable.

2, Please specify which grade you need when you order.

Example, For S grade: AR32-5

For AA grade: AR32-5AA

AAA grade is made to order. (Available in AR11, 16, 20, 25, and 32)

AR/OH coolant collet

AR/OH coolant collet is a new liquid tight collet chuck which is able to seal high pressure coolant and has gripping range from 0.1mm to 0.5mm realized with special slits.

This collet can stand water pressure of 7MPa.

This type realizes stable high precision since there is no filling in the collet.

Please refer to ALPS NICE MILL SERIES for more information. (他ページへのリンク)

AR□□OH-D

| Code | Range | Φd | Clamping Range | ΦD | L |

| AR11OH-D | 2~7 | 2,2.5,3,4,4.5,5,5.5,6,6.5,7 | 0.1 | 11 | 18 |

| AR16OH-D |

2~6 | 2,2.5,3,3.5,4,4.5,5,5.5 | 0.1 | 16 | 27 |

| 6~10 | 6,6.5,7,7.5,8,8.5,9,9.5,10 | 0.5 | |||

| AR20OH-D |

3~6 | 3,3.5,4,4.5,5,5.5 | 0.1 | 20 | 31 |

| 6~13 | 6,6.5,7,7.5,8,8.5,9,9.5,10, 10.5,11,11.5,12,12.5,13 |

0.5 | |||

| AR25OH-D |

3~6 | 3,3.5,4,4.5,5,5.5 | 0.1 | 25 | 35 |

| 6~16 | 6,6.5,7,7.5,8,8.5,9,9.5,10, 10.5,11,11.5,12,12.5,13,13.5,14,14.5,15,15.5,16 |

0.5 | |||

| AR32OH-D |

3~8 | 3,3.5,4,4.5,5,5.5,6,6.5,7,7.5 | 0.1 | 32 | 40 |

| 8~20 | 8,8.5,9,9.5,10, 10.5,11,11.5,12,12.5,13,13.5,14,14.5,15,15.5,16,16.5, 17,17.5,18,18.5,19,19.5,20 |

0.5 | |||

| AR40OH-D | 10~25 | 10,11,12,13,14,15,16,17,18,19,20,25 | 0.5 | 40 | 46 |

Notice

1, Collets in size which is not shown in the above table is made to order.

Please order by 3 pcs lot.

2, It is compatible with oil hole (OH) type drill.

3, Please insert a drill to the end of collets.

4, ALPS TOOL standard is adapted for collets in nonstandard size.

AR/GB tap collet

This is the collet for tapping tool with square rotation stopper. The stopper prevents rotation of tool during the tapping machining and realizes precise machining.

Please refer to ALPS NICE MILL SERIES for more information.

AR□□GB-□□

| Seize | CODE | ||||||

| Metric | Unified | Pipe Thread | AR16GB | AR20GB | AR25GB | AR32GB | AR40GB |

| M4 | No8U | AR16GB-M4 | AR20GB-M4 | AR25GB-M4 | AR32GB-M4 | ||

| M5 | No10U/12U | AR16GB-M5 | AR20GB-M5 | AR25GB-M5 | AR32GB-M5 | ||

| M6 | 1/4U | AR16GB-M6 | AR20GB-M6 | AR25GB-M6 | AR32GB-M6 | ||

| 5/16U | AR16GB-5/16U | AR20GB-5/16U | AR25GB-5/16U | AR32GB-5/16U | |||

| M8 | AR16GB-M8 | AR20GB-M8 | AR25GB-M8 | AR25GB-M8 | |||

| M10 | 3/8U | AR16GB-M10 | AR20GB-M10 | AR25GB-M10 | AR32GB-M10 | AR40GB-M10 | |

| M11 | 7/16U | AR16GB-7/16U | AR20GB-7/16U | AR25GB-7/16U | AR32GB-7/16U | AR40GB-7/16U | |

| PT1/8 | AR16GB-P1/8 | AR20GB-P1/8 | AR25GB-P1/8 | AR32GB-P1/8 | AR40GB-P1/8 | ||

| M12 | AR20GB-M12 | AR25GB-M12 | AR32GB-M12 | AR40GB-M12 | |||

| 1/2U | AR20GB-1/2U | AR25GB-1/2U | AR32GB-1/2U | AR40GB-1/2U | |||

| M14 | 9/16U | AR25GB-M14 | AR32GB-M14 | AR40GB-M14 | |||

| PT1/4 | AR25GB-P1/4 | AR32GB-P1/4 | AR40GB-P1/4 | ||||

| 5/8U | AR25GB-5/8U | AR32GB-5/8U | AR40GB-5/8U | ||||

| M16 | AR25GB-M16 | AR32GB-M16 | AR40GB-M16 | ||||

| PT3/8 | AR25GB-P3/8 | AR32GB-P3/8 | AR40GB-P3/8 | ||||

| M18 | 3/4U | AR32GB-M18 | AR40GB-M18 | ||||

| M20 | AR32GB-M20 | AR40GB-M20 | |||||

| M22 | 7/8U | AR40GB-M22 | |||||

| PT1/2 | AR40GB-P1/2 | ||||||

| M24 | AR40GB-M24 | ||||||

| M27 | 1U | AR40GB-M27 | |||||

Notice

1, This table is conforming to JIS standard shank.

(Please contact us about ANSI, DIN, and ISO standard shank.)

2, Tap collet for each tap size is necessary.

3, You can attach AR tap collet to collet chuck adapter if the machine uses synchro tapping.

4, Core deflection accuracy is conforming to S grade.

AR/GH coolant tap collet

This type is the collet chuck for oil hole tapping. AR/GH has better water tightening ability than AR/GB tap collet (for synchro tap machining) and can stand water pressure of 7MPa. This collet help prolong tool’s life and compatible with tapping (using long shank tap) for deep hole.

Please refer to ALPS NICE MILL SERIES for more information.

AR□□GH-□□

| Size | CODE | ||||||

| Metric | Unified | Pipe Thread | AR16GH | AR20GH | AR25GH | AR32GH | AR40GH |

| M6 | 1/4U | AR16GH-M6 | AR20GH-M6 | AR25GH-M6 | AR32GH-M6 | ||

| 5/16U | AR16GH-5/16U | AR20GH-5/16U | AR25GH-5/16U | AR32GH-5/16U | |||

| M8 | AR16GH-M8 | AR20GH-M8 | AR25GH-M8 | AR32GH-M8 | |||

| M10 | 3/8U | AR16GH-M10 | AR20GH-M10 | AR25GH-M10 | AR32GH-M10 | AR40GH-M10 | |

| M11 | 7/16U | AR16GH-7/16U | AR20GH-7/16U | AR25GH-7/16U | AR32GH-7/16U | AR40GH-7/16U | |

| PT1/8 | AR16GH-P1/8 | AR20GH-P1/8 | AR25GH-P1/8 | AR32GH-P1/8 | AR40GH-P1/8 | ||

| M12 | AR20GH-M12 | AR25GH-M12 | AR32GH-M12 | AR40GH-M12 | |||

| 1/2U | AR20GH-1/2U | AR25GH-1/2U | AR32GH-1/2U | AR40GH-1/2U | |||

| M14 | 9/16U | AR25GH-M14 | AR32GH-M14 | AR40GH-M14 | |||

| PT1/4 | AR25GH-PT1/4 | AR32GH- PT1/4 | AR40GH-PT1/4 | ||||

| 5/8U | AR25GH-5/8U | AR32GH-5/8U | AR40GH-5/8U | ||||

| M16 | AR25GH-M16 | AR32GH-M16 | AR40GH-M16 | ||||

| PT3/8 | AR25GH-P3/8 | AR32GH-P3/8 | AR40GH-P3/8 | ||||

| M18 | 3/4U | AR32GH-M18 | AR40GH-M18 | ||||

| M20 | AR32GH-M20 | AR40GH-M20 | |||||

| M22 | 7/8U | AR40GH-M22 | |||||

| PT1/2 | AR40GH-PT1/2 | ||||||

| M24 | AR40GH-M24 | ||||||

| M27 | 1U | AR40GH-M27 | |||||

Notice

1, This table is conforming to JIS standard shank.

(Please contact us about ANSI, DIN, and ISO standard shank.)

2, Tap collet for each tap size is necessary.

3, You can attach AR tap collet to collet chuck adapter if the machine uses synchro tapping.

4, Core deflection accuracy is conforming to S grade.

5, Please insert tap tooling to the end of the collet on order to prevent leaking.

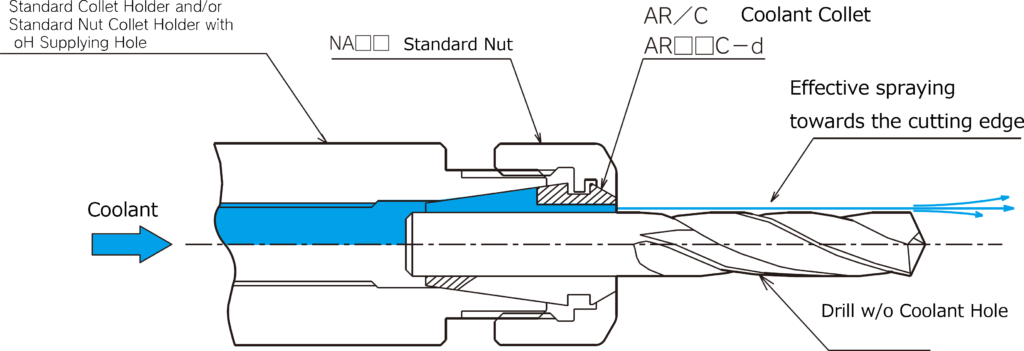

AR/C coolant collet

Coolant through is available on drills and endmills without oil hole.

・Compatible with high pressure coolant.

・Every structure except for coolant slit of this type can seal 7MPa of water pressure.

・It is possible to remove chip from edge by spraying coolant toward that part.

・This type is beneficial for small diameter deep holes that cannot be processed by oil hole drill. (compatible with oil coolant)

・It is also suitable for semi-dry machining (mist).

Please refer to ALPS NICE MILL SERIES for more information.

AR□□C-□□

| CODE | Range | Clamping Range | D | L | Applicable Holder Type |

| AR11C-d | 3~7 | 0.1 | 11 | 18 | EXH7 |

| AR16C-d | 3~5.9 | 0.1 | 16 | 27 | EXH10 |

| 6~10 | 0.5 | ||||

| AR20C-d | 5~5.9 | 0.1 | 20 | 31 | EXH13 |

| 6~13 | 0.5 | ||||

| AR25-d | 6~16 | 0.5 | 25 | 35 | EXH16 |

| AR32-d | 8~20 | 0.5 | 32 | 40 | EXH20 |

Notice

Collets in size which is not shown in the above table is made to order.

-

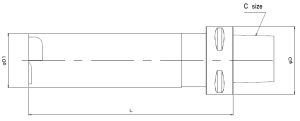

TR type milling chuck adapter

This type is suitable for rough machining with a roughing endmill.

Fastening completion signal make it easy to change tooling.

No need for optional item. Become compatible with center through/ side through only by changing collets. (7MPa)

AC4-TRX□□-□□

| CAPTO | Dimension | |||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | Wrench |

| AC4 | AC4-TRX16-70 | AS16-d | 16 | 40 | 45 | 70 | 65 | FK-7 |

| AC4-TRX20-75 | AS20-d | 20 | 52 | 75 | 69 | FK-8 | ||

AC5-TRX□□-□□

| CAPTO | Dimension | |||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | Wrench |

| AC5 | AC5-TRX16-70 | AS16-d | 16 | 50 | 45 | 70 | 65 | FK-7 |

| AC5-TRX16-90 | 90 | |||||||

| AC5-TRX20-75 | AS20-d | 20 | 52 | 75 | 70 | FK-8 | ||

| AC5-TRX20-90 | 90 | |||||||

| AC5-TRX25-80 | AS25-d | 25 | 63 | 80 | 76 | FK-9 | ||

| AC5-TRX25-105 | 105 | |||||||

| AC5-TRX32-85 | AS32-d | 32 | 75 | 85 | 77 | FK-10 | ||

AC6-TRX□□-□□

| CAPTO | Dimension | |||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | Wrench |

| AC6 | AC6-TRX16-70 | AS16-d | 16 | 63 | 45 | 70 | 65 | FK-6 |

| AC6-TRX16-90 | 90 | |||||||

| AC6-TRX16-105 | 105 | |||||||

| AC6-TRX16-135 | 135 | |||||||

| AC6-TRX20-75 | AS20-d | 20 | 52 | 75 | 71 | FK-8 | ||

| AC6-TRX20-90 | 90 | |||||||

| AC6-TRX20-105 | 105 | |||||||

| AC6-TRX20-135 | 135 | |||||||

| AC6-TRX25-80 | AS25-d | 25 | 63 | 80 | 76 | FK-9 | ||

| AC6-TRX25-105 | 105 | |||||||

| AC6-TRX25-135 | 135 | |||||||

| AC6-TRX32-90 | AS32-d | 32 | 75 | 90 | 84 | FK-10 | ||

| AC6-TRX32-105 | 105 | |||||||

| AC6-TRX32-135 | 135 | |||||||

| AC6-TEX42-100 | AS42-d | 42 | 92 | 100 | 90 | FK-12 | ||

AC8-TRX□□-□□

| CAPTO | Dimension | |||||||

| SIZE | CODE | Collet CODE | d | D | D1 | l1 | l2 | Wrench |

| AC8 | AC8-TRX16-105 | AS16-d | 16 | 80 | 45 | 105 | 65 | FK-7 |

| AC8-TRX16-135 | 135 | |||||||

| AC8-TRX16-165 | 165 | |||||||

| AC8-TRX20-85 | AS20-d | 20 | 52 | 85 | 71 | FK-8 | ||

| AC8-TRX20-105 | 105 | |||||||

| AC8-TRX20-135 | 135 | |||||||

| AC8-TRX20-165 | 165 | |||||||

| AC8-TRX25-90 | AS25-d | 25 | 63 | 90 | 80 | FK-9 | ||

| AC8-TRX25-105 | 105 | |||||||

| AC8-TRX25-135 | 135 | |||||||

| AC8-TRX25-165 | 165 | |||||||

| AC8-TRX32-100 | AS32-d | 32 | 75 | 100 | 90 | FK-10 | ||

| AC8-TRX32-105 | 105 | |||||||

| AC8-TRX32-135 | 135 | |||||||

| AC8-TRX32-165 | 165 | |||||||

| AC8-TRX42-105 | AS42-d | 42 | 92 | 105 | 95 | FK-12 | ||

Notice

1, Center through coolant is available as standard.

2, Side through coolant becomes available by removing set bolt from the end face.

3, Standard product is compatible slit through coolant when is used in combination with a straight collet.

Products with oil hole are compatible with center through coolant.

4, Some products cannot clamp tooling when shank is installed to the end of the adapter while draw bolt is clamped.

5, A spanner is not supplied.

-

Side lock adapter

Firmly fix milled tooling.

AC5-SLA□□-□□

| CAPTO | |||||

| SIZE | CODE | d | D1 | L | l2 |

| C5 | AC5-SLA20-65 | 20 | 50 | 65 | 60 |

| AC5-SLA25-75 | 25 | 55 | 75 | 65 | |

| AC5-SLA32-82 | 32 | 60 | 80 | 70 | |

| AC5-SLA40-100 | 40 | 66 | 100 | 72 | |

AC6-SLA□□-□□

| CAPTO | |||||

| SIZE | CODE | d | D1 | L | l2 |

| C6 | AC6-SLA20-70 | 20 | 50 | 70 | 60 |

| AC6-SLA25-75 | 25 | 55 | 75 | 65 | |

| AC6-SLA32-80 | 32 | 60 | 80 | 70 | |

| AC6-SLA40-85 | 40 | 66 | 85 | 75 | |

| AC6-SLA42-85 | 42 | 70 | 85 | 75 | |

AC8-SLA□□-□□

| CAPTO | |||||

| SIZE | CODE | d | D1 | L | l2 |

| C8 | AC8-SLA20-80 | 20 | 50 | 80 | 65 |

| AC8-SLA25-85 | 25 | 55 | 85 | 70 | |

| AC8-SLA32-90 | 32 | 60 | 90 | 75 | |

| AC8-SLA40-95 | 40 | 66 | 95 | 80 | |

| AC8-SLA42-95 | 42 | 70 | 95 | 80 | |

-

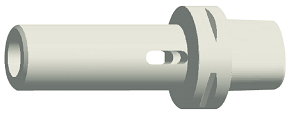

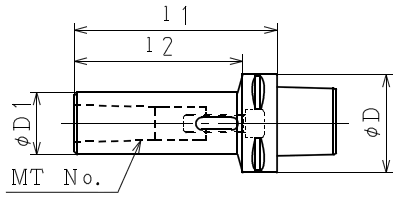

Morse taper adapter

Used in combination with Morse taper drill.

AC3-MTA□□-□□

| CAPTO | Dimension | ||||||

| SIZE | CODE | Morse Taper | D | D1 | l1 | l2 | Pull bolt |

| C3 | AC3-MTA1-90 | 1 | 32 | 25 | 90 | 71.5 | M6×30 |

| AC3-MTA2-95 | 2 | 32 | 95 | 80 | Not Available | ||

AC4-MTA□□-□□

| CAPTO | Dimension | ||||||

| SIZE | CODE | Morse Taper | D | D1 | l1 | l2 | Pull bolt |

| C4 | AC4-MTA1-90 | 1 | 40 | 25 | 90 | 68 | M6×30 |

| AC4-MTA2-95 | 2 | 32 | 95 | 73 | Not Available | ||

| AC4-MTA3-115 | 3 | 40 | 115 | 95 | |||

AC5-MTA□□-□□

| CAPTO | Dimension | ||||||

| SIZE | CODE | Morse Taper | D | D1 | l1 | l2 | Pull bolt |

| C5 | AC5-MTA1-95 | 1 | 50 | 25 | 95 | 75 | M6×35 |

| AC5-MTA2-105 | 2 | 32 | 105 | 82 | M10×35 (Special) | ||

| AC5-MTA3-115 | 3 | 40 | 115 | 95 | Not Available | ||

| AC5-MTA4-145 | 4 | 52 | 145 | 125 | |||

AC6-MTA□□-□□

| CAPTO | Dimension | ||||||

| SIZE | CODE | Morse Taper | D | D1 | l1 | l2 | Pull bolt |

| C6 | AC6-MTA1-95 | 1 | 63 | 25 | 95 | 70 | M6×35 |

| AC6-MTA2-110 | 2 | 32 | 110 | 83 | M10×35 | ||

| AC6-MTA3-130 | 3 | 40 | 130 | 104 | M12×40 (Special) | ||

| AC6-MTA4-150 | 4 | 52 | 150 | 124 | Not Available | ||

| AC6-MTA5-180 | 5 | 68 | 180 | 158 | |||

AC8-MAT□□-□□

| CAPTO | 型式 | Dimension | |||||

| SIZE | Morse Taper | D | D1 | l1 | l2 | Pull bolt | |

| C8 | AC8-MTA1-85 | 1 | 80 | 25 | 85 | 42 | M6×35 |

| AC8-MTA2-100 | 2 | 32 | 100 | 53 | M10×35 | ||

| AC8-MTA3-120 | 3 | 40 | 120 | 70 | M12×40 (Special) | ||

| AC8-MTA4-150 | 4 | 52 | 150 | 112 | Not Available | ||

| AC8-MTA5-185 | 5 | 68 | 185 | 151 | |||

Notice

Pull-screw is not supplied.

-

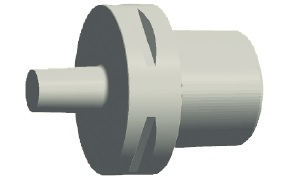

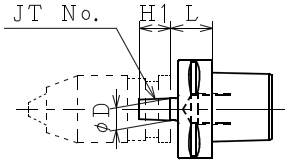

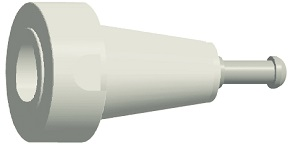

Jacobs taper holder

The holder to attach drill chuck. Straight drills can be chucked easily.

AC5-JTA□-□□

| CAPTO | Dimension | Drill Chuck (ALBRECHT) | ||||

| SIZE | CODE | JT No. | D | L | H1 | Drill Chuck |

| C5 | AC5-JTA2-25 | 2 | 14.199 | 25 | 20 | 100-J2 |

| AC5-JTA6-25 | 6 | 17.17 | 24 | 130-J6 , 160-J6 | ||

AC6-JTA□-□□

| CAPTO | Dimension | Drill Chuck (ALBRECHT) | ||||

| SIZE | CODE | JT No. | D | L | H1 | Drill Chuck |

| C6 | AC6-JTA2-27 | 2 | 27 | 20 | 100-J2 | |

| AC6-JTA6-27 | 6 | 24 | 130-J6 , 160-J6 | |||

AC8-JTA□-□□

| CAPTO | Dimension | Drill Chuck (ALBRECHT製) | ||||

| SIZE | CODE | JT No. | D | L | H1 | Drill Chuck |

| C8 | AC8-JTA2-35 | 2 | 14.199 | 35 | 20 | 100-J2 |

| AC8-JTA6-35 | 6 | 17.17 | 24 | 130-J6 , 160-J6 | ||

Notice

Drill chuck is not supplied.

-

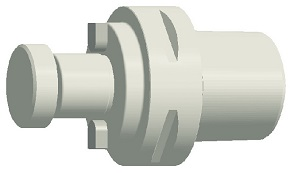

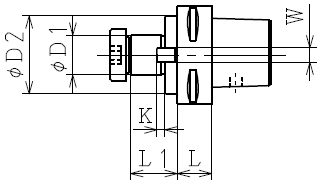

Face mill adapter

The arbor compatible with JIS B4133 face mill.

This product firmly fixes milling cutter and can be used widely including facing to rough machining.

AC4-FMA□□-□□

| CAPTO | Dimension | |||||||

| SIZE | CODE | D1 | D2 | L | L1 | W | K | M |

| C4 | AC4-FMA25.4-35 | 25.4 | 50 | 35 | 22 | 9.5 | 5 | M12 |

AC5-FMA□□-□□

| CAPTO | Dimension | |||||||

| SIZE | CODE | D1 | D2 | L | L1 | W | K | M |

| C5 | AC5-FMA25.4-30 | 25.4 | 50 | 30 | 22 | 9.5 | 5 | M12 |

| AC5-FMA31.75-35 | 31.75 | 60 | 35 | 30 | 12.7 | 7 | M16 | |

AC6-FMA□□-□□

| CAPTO | Dimension | |||||||

| SIZE | CODE | D1 | D2 | L | L1 | W | K | M |

| C6 | AC6-FMA25.4-30 | 25.4 | 50 | 30 | 22 | 9.5 | 5 | M12 |

| AC6-FMA25.4-60 | 60 | |||||||

| AC6-FMA25.4-90 | 90 | |||||||

| AC6-FMA31.75-30 | 31.75 | 60 | 30 | 30 | 12.7 | 7 | M16 | |

| AC6-FMA31.75-90 | 90 | |||||||

| AC6-FMA38.1-40 | 38.1 | 80 | 40 | 34 | 15.9 | 9 | M20 | |

AC8-FMA□□-□□

| CAPTO | Dimension | |||||||

| SIZE | CODE | D1 | D2 | L | L1 | W | K | M |

| C8 | AC8-FMA25.4-40 | 25.4 | 50 | 40 | 22 | 9.5 | 5 | M12 |

| AC8-FMA25.4-75 | 75 | |||||||

| AC8-FMA25.4-105 | 105 | |||||||

| AC8-FMA31.75-40 | 31.75 | 60 | 40 | 30 | 12.7 | 7 | M16 | |

| AC8-FMA31.75-90 | 90 | |||||||

| AC8-FMA38.1-40 | 38.1 | 80 | 40 | 34 | 15.9 | 9 | M20 | |

| AC8-FMA47.625-60 | 17.625 | 128.57 | 60 | 38 | 25.4 | 12.5 | M16 | |

| AC8-FMA50.8-50 | 50.8 | 100 | 50 | 36 | 19.05 | 10 | M24 | |

-

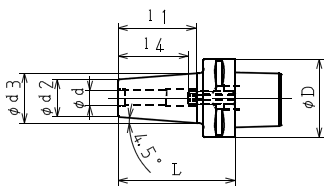

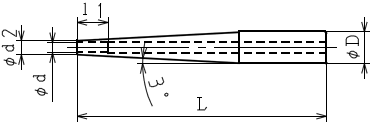

Shrinkage fitting chuck adapter

The holder for high precision machining.

Please refer to Thermo Grip for more information.

AC5-TG□□-□□

| CAPTO | Dimension | |||||||||

| SIZE | CODE | FIG. | Tool material | d | D | L | d2 | d3 | l1 | l4 |

| C5 | AC5-TG6-75 | 1 | HSS / Carbide | 6 | 50 | 75 | 20 | 27 | 36 | 26~30 |

| AC5-TG8-75 | 8 | 48 | 26~48 | |||||||

| AC5-TG10-75 | 10 | 24 | 32 | 50 | 32~50 | |||||

| AC5-TG12-75 | 12 | 55 | 37~55 | |||||||

| AC5-TG16-80 | 16 | 80 | 27 | 34 | 40~55 | |||||

| AC5-TG20-85 | 20 | 85 | 33 | 42 | 65 | 45~54 | ||||

AC6-TG□□-□□

| Dimension | ||||||||||

| SIZE | CODE | FIG. | Tool material | d | D | L | d2 | d3 | l1 | l4 |

| C6 | AC6-TG6-80 | 1 | HSS / Carbide | 6 | 63 | 80 | 20 | 27 | 36 | 26~36 |

| AC6-TG8-80 | 8 | 48 | 26~48 | |||||||

| AC6-TG10-80 | 10 | 24 | 32 | 50 | 32~50 | |||||

| AC6-TG12-80 | 12 | 55 | 37~55 | |||||||

| AC6-TG16-85 | 16 | 85 | 27 | 34 | 40~55 | |||||

| AC6-TG20-90 | 20 | 90 | 33 | 42 | 65 | 45~65 | ||||

| AC6-TG25-90 | 25 | 44 | 53 | 70 | 50~70 | |||||

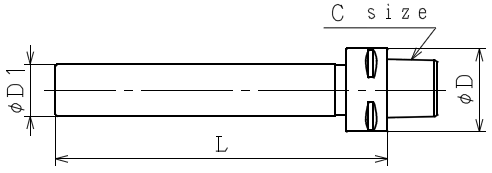

SS□□-TG□□■■-□□

| SHANK | Dimension | |||||||||

| SIZE | CODE | FIG. | Tool material | d | D | L | d2 | d3 | l1 | l4 |

| Φ20 | SS20-TG4C-200 | 2 | Carbide | 4 | 20 | 200 | 12 | – | 16 or More | – |

| Φ25 | SS25-TG4C-200 | 25 | ||||||||

| SS25-TG6SS-200 | 6 | 9 | 36 or More | |||||||

| SS25-TG8SS-200 | 8 | 11 | 48 or More | |||||||

| SS25-TG10SS-200 | 10 | 13 | 50 or More | |||||||

| SS25-TG12SS-200 | 12 | 15 | 60 or More | |||||||

Notice

1, Please use our Thermo Grip heating device for shrinkage fitting.

2, We offer variety of shrinkage fitting holder for straight shank besides products on the table above.

-

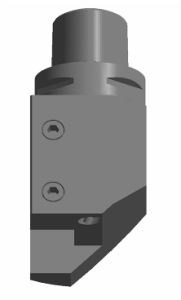

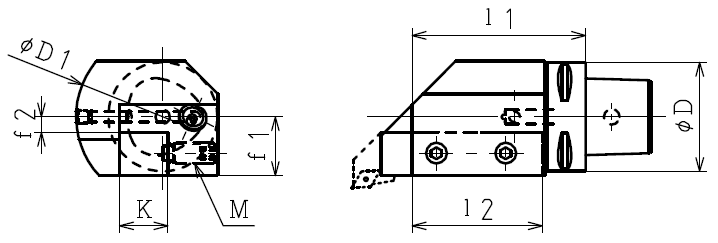

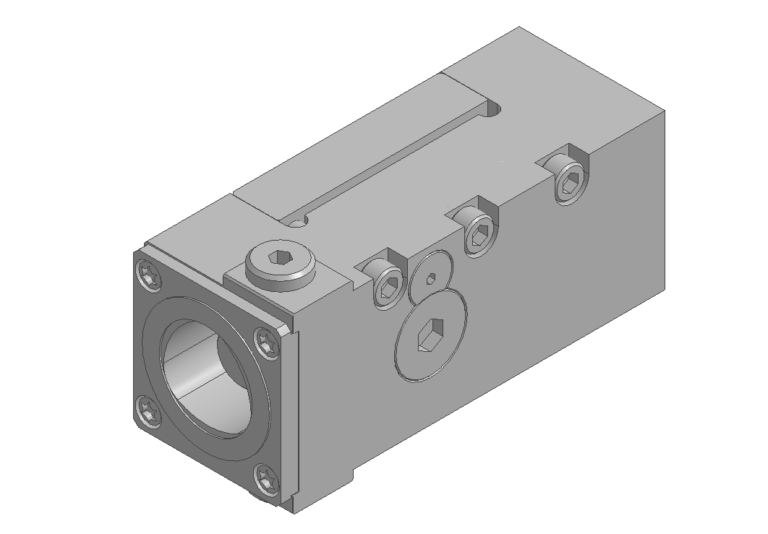

Fine boring unit adapter

The boring adapter conforming to T-MAX, U type B unit by Sandvik.

AC3-BTB□□-□□

| CAPTO | Dimension | ||||||||

| SIZE | CODE | FIG. | D | L | M1 | C1 | C2 | FB Unit Code | Insert |

| C3 | AC3-BTB26.0-90 |

1 | 26.0~30 | 90 | 69 | 23 | 23.6 | L148C-31-06 02 | CCMT0602 |

| (25.9~29.6) | (L148C-31-06 T1) | (TCNT0602) | |||||||

| AC3-BTB29.6-90 |

29.6~33 | 70 | 26 | 26.6 | |||||

| (29.2~33.2) | |||||||||

| AC3-BTB33.1-110 | 33.1~38.7 | 110 | 90 | 29 | 29.6 | L148C-33-09 02 | TCMT0902 | ||

| AC3-BTB38.2-40 | 2 | 38.2~43.8 | 40 | – | 34 | – | |||

| AC3-BTB43.3-50 | 43.3~52.9 | 50 | 39 | L148C-33-11 02 | TCMT1102 | ||||

AC4-BTB□□-□□

| CAPTO | Dimension | ||||||||

| SIZE | CODE | FIG. | D | L | M1 | C1 | C2 | FB Unit Code | Insert |

| C4 | AC4-BTB33.1-120 | 1 | 33.1~38.7 | 120 | 90 | 29 | 29.6 | L148C-32-09 02 | TCMT0902 |

| AC4-BTB38.2-135 | 38.2~43.8 | 135 | 103 | 34 | 35 | ||||

| AC4-BTB43.3-60 | 2 | 43.3~52.9 | 60 | – | 39 | – | L148C-32-11 02 | TCMT1102 | |

| AC4-BTB52.4-60 | 52.4~62.0 | 48 | |||||||

| AC4-BTB61.5-60 | 61.5~71.1 | 57 | |||||||

AC5-BTB□□-□□

| CAPTO | Dimension | ||||||||

| SIZE | CODE | FIG. | D | L | M1 | C1 | C2 | FB Unit Code | Insert |

| C5 | AC5-BTB43.3-150 | 1 | 43.3~52.9 | 150 | 122 | 39 | 40 | L148C-33-11 02 | TCMT1102 |

| AC5-BTB25.4-165 | 52.9~62.0 | 165 | 140 | 48 | 49 | ||||

| AC5-BTB61.5-60 | 2 | 61.5~71.1 | 60 | – | 57 | – | |||

| AC5-BTB70.6-60 | 70.6~80.2 | 66 | |||||||

| AC5-BTB79.7-60 | 79.7~89.2 | 75 | |||||||

| AC5-BTB88.8-60 | 88.8~98.4 | 84 | |||||||

| AC5-BTB97.9-60 | 97.9~107.5 | 93 | |||||||

Notice

1, Machining diameter is R0.4 of tip nose.

2, FB unit and a chip are not supplied.

-

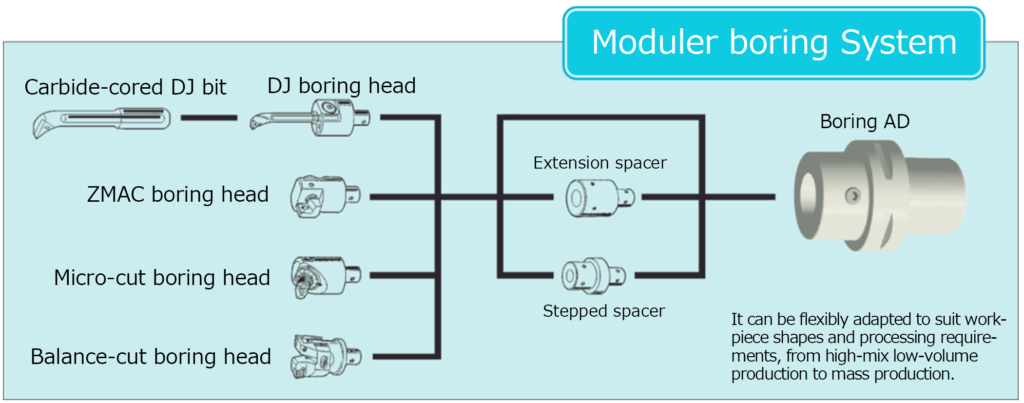

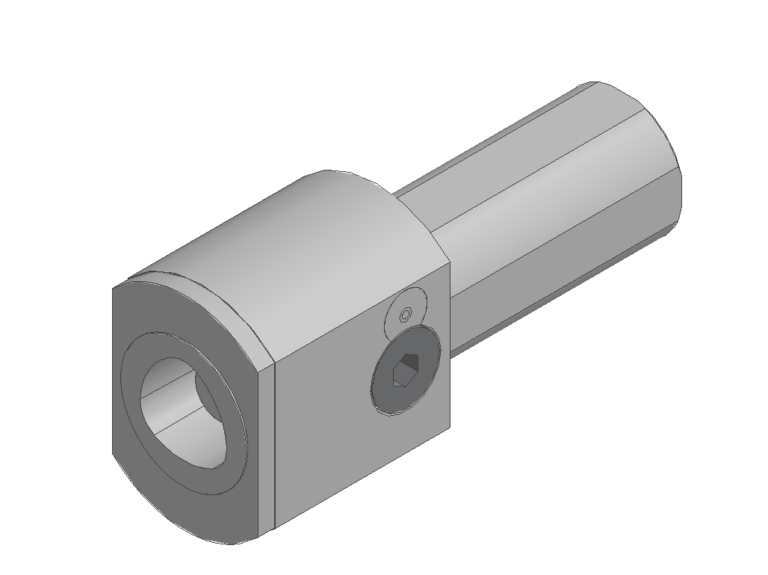

Modular boring adapter

Please use boring head produced by NIKKEN KOSAKUSHO WORKS, LTD.

AC5-Q□□-□□

| CAPTO | Dimension | ||||||

| SIZE | CODE | Q | D | L | H | Coupling Bolt | Boring dia. |

| C5 | AC5-Q26-50 | 26 | 50 | 50 | 30 | B26N | Φ3~Φ70 |

AC6-Q□□-□□

| CAPTO | Dimension | ||||||

| SIZE | CODE | Q | D | L | H | Coupling Bolt | Boring dia. |

| C6 | AC6-Q26-50 | 26 | 50 | 50 | 28 | B26N | Φ3~Φ70 |

| AC6-Q34-55 | 34 | 64 | 55 | 33 | B34 | Φ70~Φ85 | |

AC8-Q□□-□□

| CAPTO | Dimension | ||||||

| SIZE | CODE | Q | D | L | H | Coupling Bolt | Boring dia. |

| C8 | AC8-Q26-60 | 26 | 50 | 60 | 30 | B26N | Φ3~Φ70 |

| AC8-Q34-60 | 34 | 64 | B34 | Φ70~Φ85 | |||

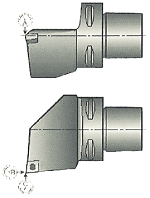

Turning tool

-

Square shank holder adapter (B type)

AC□-ABSB101-□□□L/R , 0°right hinge 0°left hinge

Notice

R: right hinge L: left hinge

-

Square shank holder adapter (C type)

90°right hinge 90°left hinge

90°both hinge

Notice

R: right hinge L: left hinge

-

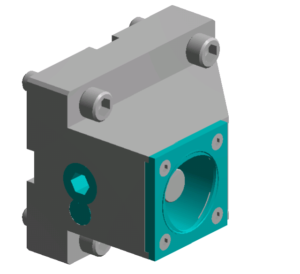

Collet holder (Short type holder)

You can utilize tooling area owing to its short projection length.

It is suitable for turning tool including drills, endmills, and reamers.

Size of short type adapter interface.

Notice

1, it is compatible only with segment.

(It cannot be used as a holder for center bolt clamp)

2, It is not compatible with ATC.

3, Please order a spanner separately.

4, Center through coolant is available as a standard.

-

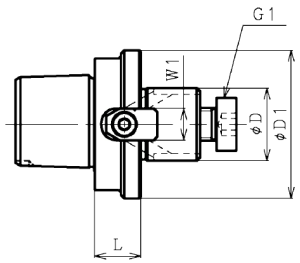

Side lock adapter (Short type holder)

You can utilize tooling area owing to its short projection length.

It is suitable for turning tool including boring bar and U type drills.

Notice

1, it is compatible only with segment.

(It cannot be used as a holder for center bolt clamp)

2, It is not compatible with ATC.

3, Please order a spanner separately.

4, Center through coolant is available as a standard.

-

Face mill adapter (Short type holder)

You can utilize tooling area owing to its short projection length.

It is suitable for facing tool.

Notice

1, it is compatible only with segment.

(It cannot be used as a holder for center bolt clamp)

2, It is not compatible with ATC.

3, Please order a spanner separately.

-

Screw in adapter (Short type holder)

You can utilize tooling area owing to its short projection length.

It is suitable for turning tool.

Screw-in cutter is available on this adapter.

Notice

1, it is compatible only with segment.

(It cannot be used as a holder for center bolt clamp)

2, It is not compatible with ATC.

3, Please order a spanner separately.

-

Square shank clamping unit

ALPS CAPTO can be instantly installed to grooves of square shank holders (wedge type).

Notice

You can choose between right handed one or left handed one.

-

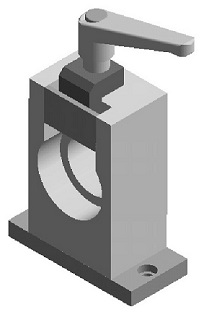

Round shank clamping unit

ALPS CAPTO can be instantly introduced to the round shank holder.

Cam type

Pull-screw type

Notice

1, D1 shank has four milled dimensions.

2, Please finish piping before you use the intimal coolant.

3, We offer special support for mounting diameter. Please feel free to ask us.

-

Adapter for presetter

The adapter to attach ALPS CAPTO to a presetter.

Please use NIHON ID SYSTEM’s TP-400 or TP-300 type prestter.

Notice

・Please use with hydraulic clamp (option).

・Tool length adjustment bolt for tool pre-setting is available.

(Option).

-

Adapter for master gage

The master gage for presetter. It is possible to check the phase.

-

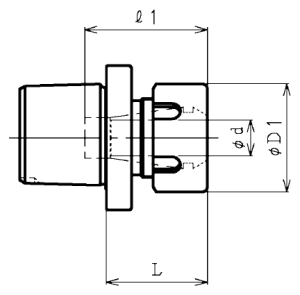

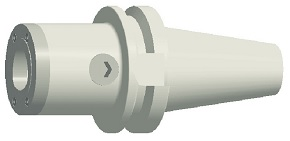

BT shank QC holder

The adapter for quick change from BT shank to a capto.

The adapter to easily attach BT shank to a presetter.

(deflection accuracy is 20㎛.)

-

Sensor holder

The holder to attach a sensor including touch sensor produces by RENISHAW.

Please contact us for more information.

-

Test bar

Coaxiality can be checked.

-

Tool clamp base

Tool clamp for ALPS CAPTO.

It is possible to use tool with turned-up by moving the base.

-

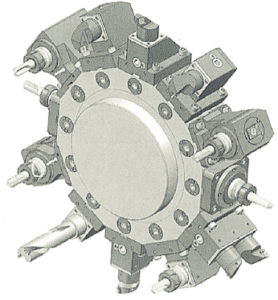

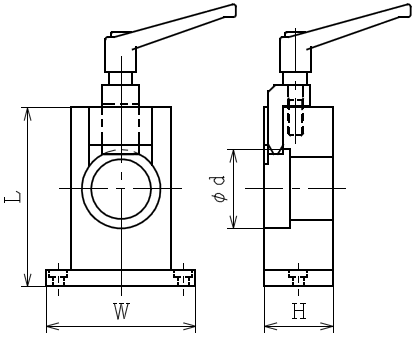

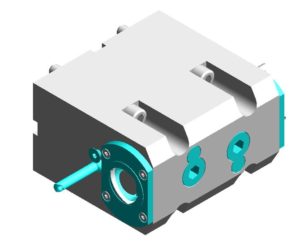

quick change system for turret

It is possible to standardize or make them QC easily by attaching ALPS TOOL original QC holder to turret of CNC lathes and compound machining center.

Original QC holder is compatible with turning tool and rotating tool.

Notice

1, Please contact us if you intend to use ALPS CAPTO QC holder.

2, We offer special QC holder if you need.

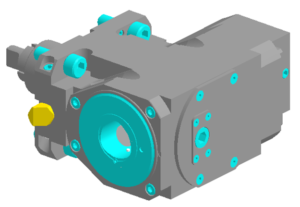

ALPS CAPTO QC

ALPS CAPTO Quick Change tooling system.

Cost for tooling can be reduced and time for changing tool, test machining, and measurement can be shortened by mounting quick change system on compound machining centers and CNC lathes

Overview

ALPS CAPTO is dihedral constraint type coupling which has polygon formed 1/20 taper.

Quick change system and tool sharing between lathes and machining center realize cost reduction and higher productivity.

-

Cutting head data NLX (NL)/ NZX/ NT

1, Turning tool holder for external diameter: NLX (NL) / NZX / NT

AC5-SSMS100-40000

AC5-SSMS100-40000L

AC5-SSMS100-47000

2, Double-headed turning tool holder for external diameter: NLX (NL) / NZX / NT

AC5-SSMS100-41000

3, Turning tool holder for internal diameter: NLX (NL) / NZX / NT

AC5-SRMS100-42000

AC5-SRMS100-46000

AC5-SRMS100-49000

AC6-SRMS100-56000

4, Double-headed turning holder for internal diameter: NLX (NL) / NZX / NT

AC5-SRMS100-43000

5, Rotating holder foe external diameter: NLX (NL) / NZX / NT

6, Double-headed rotating holder for end face. NLX (NL) / NZX / NT

7, Rotating holder for end face. NLX (NL) / NZX / NT

8, Rotating holder with oil hole for end face. NLX (NL) / NZX / NT

Notice

This drawing shows the direction of chip (upward/ downward) for NL type.

Direction of turret for NT type gets opposite.

-

Cutting head data NLX/ NZX/ DuraTurn/ NTX/ NT

1, Turning tool holder for external diameter: NLX/ NZX/ DuraTurn/ NTX/ NT

AC4-SSMS100-5000

2, Double-headed turning tool holder for external diameter: NLX/ NZX/ DuraTurn/ NTX/ NT

AC4-SRMS100-51000

3, Turning tool holder for internal diameter: NLX/ NZX/ DuraTurn/ NTX/ NT

AC4-AMS100-WA

4, Double-headed turning holder for internal diameter: NLX/ NZX/ DuraTurn/ NTX/ NT

AC4-AMS100-WB

5, Rotating holder foe external diameter:NLX/ NZX/ DuraTurn/ NTX/ NT

6, Double-headed rotating holder for end face. NLX/ NZX/ DuraTurn/ NTX/ NT

7, Rotating holder for end face. NLX/ NZX/ DuraTurn/ NTX/ NT

8, Rotating holder with oil hole for end face. NLX/ NZX/ DuraTurn/ NTX/ NT

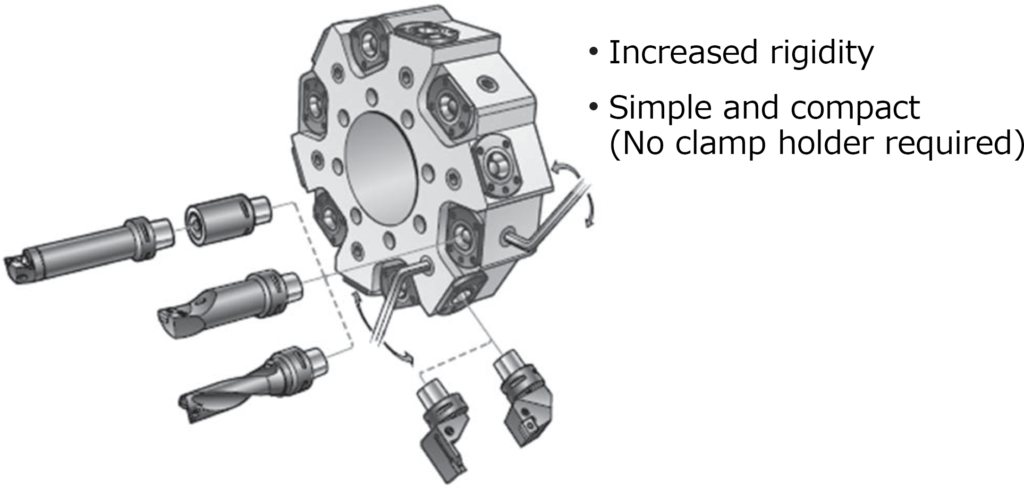

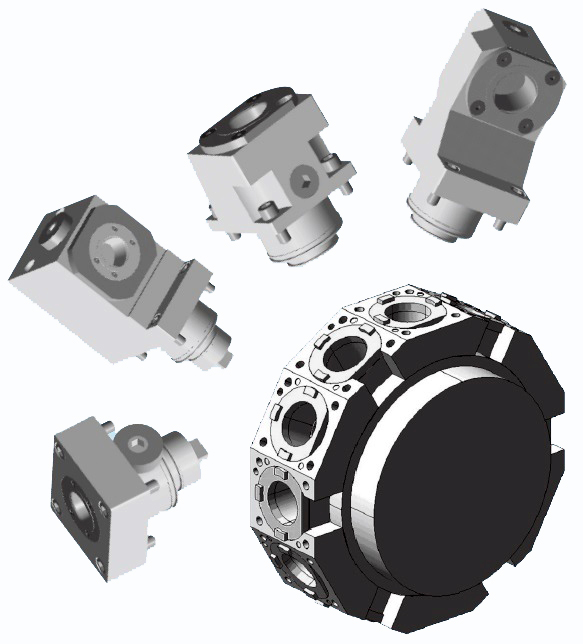

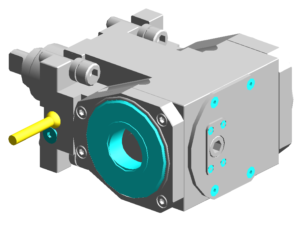

CDI type quick change

CDI (ALPS CAPTO Disc Interface) help share tooling for turret.

Advantages of CDI

1, Fixed tool, turning tool, and standard tool of ALPS CAPTO become one interface.

2, Wider machining range become available owing to more compact and higher rigidity than that of VDI.

Accelerating tool change on lathes manufacturers and machines.

Quick change can be realized by quipping our original quick change holder to CNC lathes and multi task machining.

Please specify following factor and we evaluate if it is possible to realize ALPS CAPTO quick change.

1, Manufacturer, model name

2, Fixed tool (For external and internal diameter…)

3, Turning tool (For external and internal diameter…)

4, Diameter of cutting tool, projecting length

Clamping unit: Attention (Turning, fixed tool)

Please follow instructions below when you use clamping unit.

1, Please read and follow manual when you use.

2, Please pour specified grease to cam every 6 months.

3, Please stop operating and contact us as soon as you notice unusual noise or movement.

4, Please use this unit under the appropriate circumstance for this product.