Nice Mill

-

Feature of AR collet chuck system

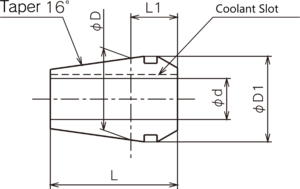

・European standard 16°tapered (DIN6499/ ISO15488) collet.

・We offer several series of products which range from φ0.3 to φ34.

・We can offer special sleeve in short delivery time.

Gripping ability

・Each collet chuck has gripping range (-0.2mm to 2mm)

Notice

1, Gripping range differs in following case.

2, They cannot grip tools beyond its nominal diameter.

| Code | Range (mm) |

| AR16-Φ1 , AR20-Φ1 , AR25-Φ1 | 0.5 |

| AR8-Φ0.5 | 0.2 |

| AR50 | 2.0 |

Deflection accuracy

・We are challenging to realize accuracy of a micro-level based on our achievement as a professional manufacturer.

・We offer high quality products stably by utilizing ISO9001.

| ID | L | Run out Accuracy | |||

| d | AR8~AR40 | AR50 | AAA | AA | A |

| 1~1.5 | 4×d | 4×d | ※ 3μ | ※ 5μ | 8μ |

| 2~5.5 | |||||

| 6~10 | 25 | ||||

| 11~26 | 40 | ||||

| 28~34 | – | 60 | – | 10μ | 18μ |

Products marked ※ is made to order.

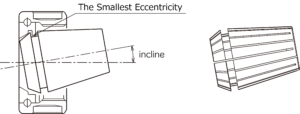

Attach/ detach chuck collet

・Easy and certain

・Chuck can be attached/ detached after fitting slit on chuck into the smallest eccentricity section of thrust ring. Both ends of collets and nuts has been improved and become flat and able to cramp to the end of cutting tool.

Recommended tightening torque for nuts

| Code | ID | Torque (N・m) |

| AR8 | Φ0.5~Φ5.0 | 10 |

| AR11 | Φ1.0~Φ3.0 | 15 |

| Φ3.5~Φ7.0 | 20 | |

| AR16 | Φ1.0~Φ3.0 | 30 |

| Φ3.5~Φ10.0 | 40 | |

| AR20 | Φ1.0~Φ3.0 | 40 |

| Φ3.5~Φ14.0 | 60 | |

| AR25 | Φ1.0~Φ3.0 | 40 |

| Φ3.5~Φ16.0 | 60 | |

| AR32 | Φ3.0~Φ20.0 | 70 |

| AR40 | Φ4.0~Φ26.0 | 80 |

| AR50 | Φ6.0~Φ34.0 | 140 |

Notice

・Nuts and collets can be broken and lose its accuracy if you tight them too much.

We offer NA torque spanners which help preventing over tightening.

Tightening accuracy can be improved since recommended torque is visible with this spanner.

Object: NA11, NA16

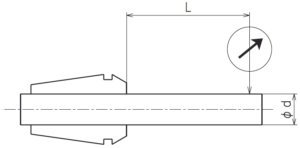

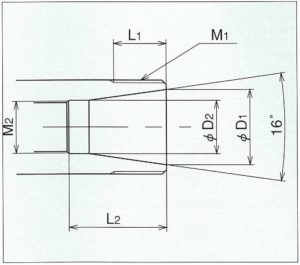

Holder standards

| CODE | D1 | D2 | M1 | M2 | min L1 | min L2 | Collet Chuck |

| □-ECH5S-□ | 8 | 5.2 | M10×0.75 | – | 7.5 | – | AR 8 |

| □-ECH 7-□ | 11 | 8.2 | M14×0.75 | M8×1.0 | 8 | 15 | AR11 |

| □-ECH10-□ | 16 | 11.2 | M22×1.5 | M11×1.0 | 13 | 23 | AR16 |

| □-ECH13-□ | 20 | 14.2 | M25×1.5 | M14×1.0 | 14 | 26 | AR20 |

| □-ECH16-□ | 25 | 18.3 | M32×1.5 | M18×1.5 | 15 | 30 | AR25 |

| □-ECH20-□ | 32 | 24.3 | M40×1.5 | M24×1.5 | 16 | 34 | AR32 |

| □-ECH26-□ | 40 | 31 | M50×1.5 | M28×1.5 | 16 | 38 | AR40 |

| □-ECH34-□ | 50 | 38 | M64×2.0 | – | 24 | – | AR50 |

Notes

1, The above list is reference standards. Please ask us for more information.

2, We offer taper gage as well.

3, We offer special spindles. Please feel free to contact us for order.

4, The numerical values in above table differ when you use M-nut.

-

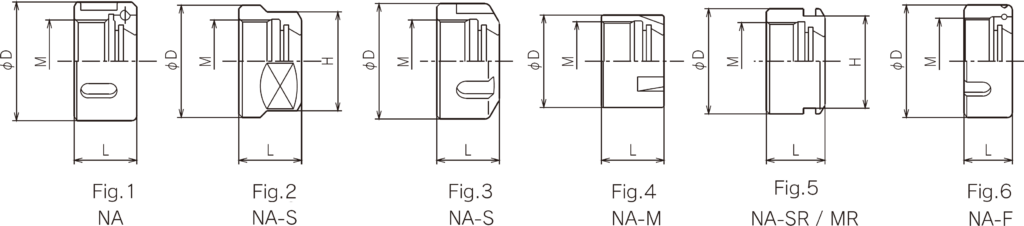

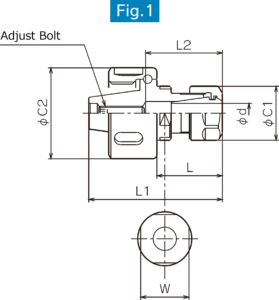

NA nut / high speed nut / spanner

・The nuts and spanners suitable for after parts of drill holders, tap holders, and rotating tools.

・A nut which has narrower width would be suitable, in case components are mutually interfered.

・Please replace standard nuts with nuts for high speed rotary machining when high speed machining.

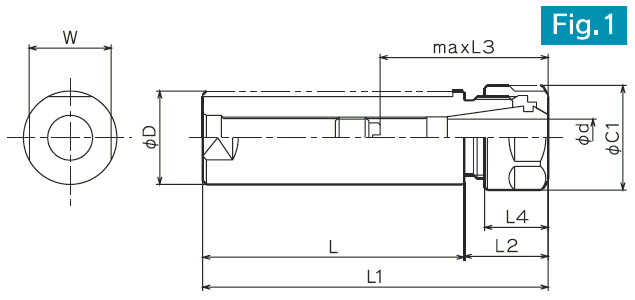

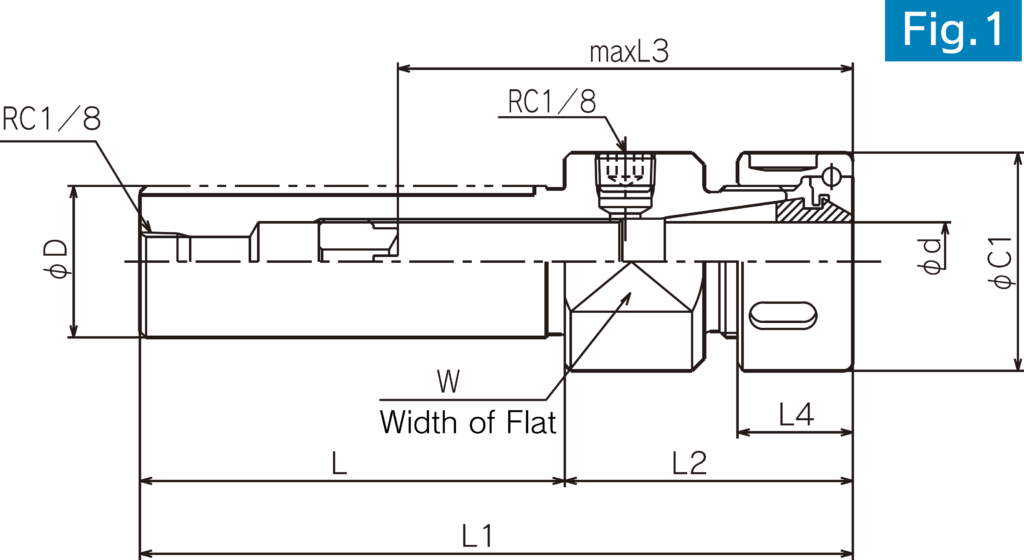

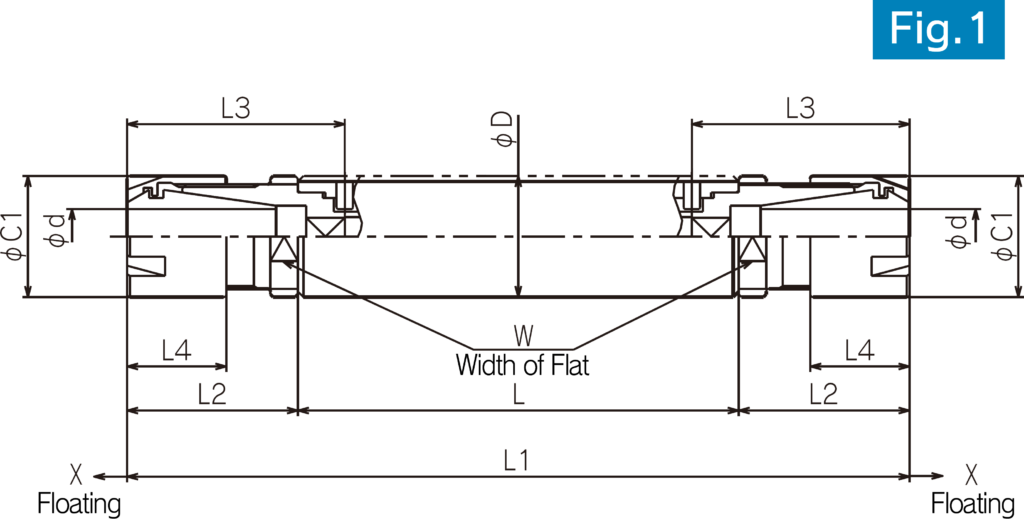

NA type (Fig.1)

・This sealed type nut with a ball bearing realizes high runout accuracy.

・30% better gripping power than that of S type.

・Suitable for deep cutting.

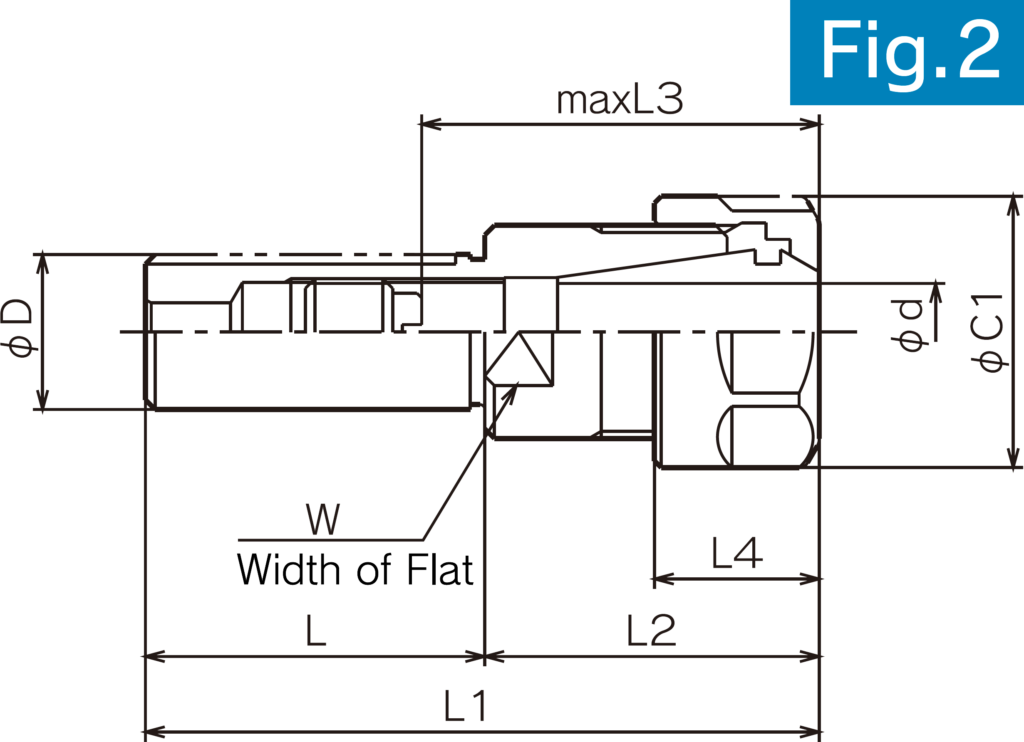

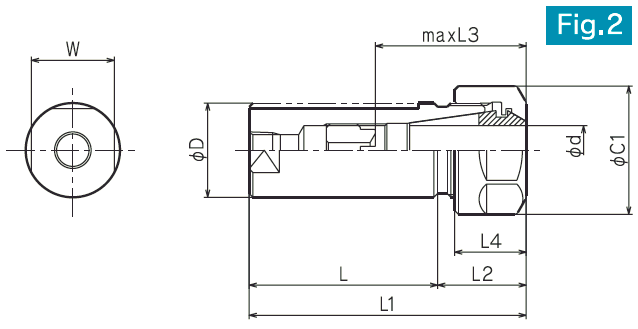

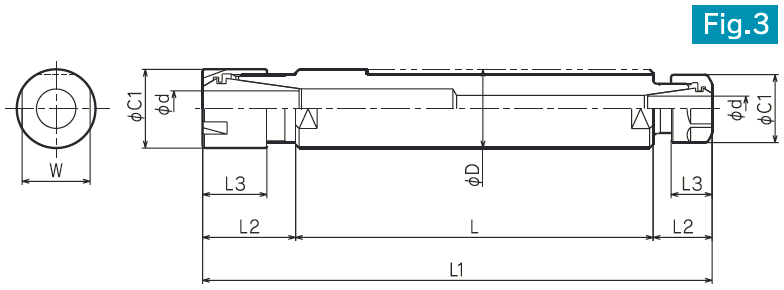

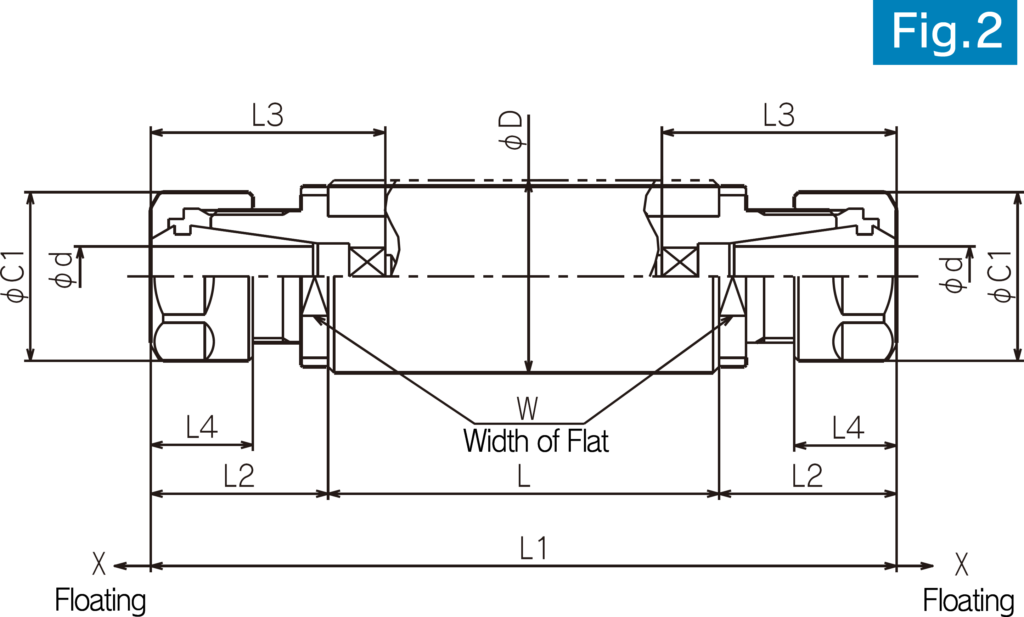

NA-S type (Fig.2/ 3)

・This type prevents tool interference since is more compact than the other types.

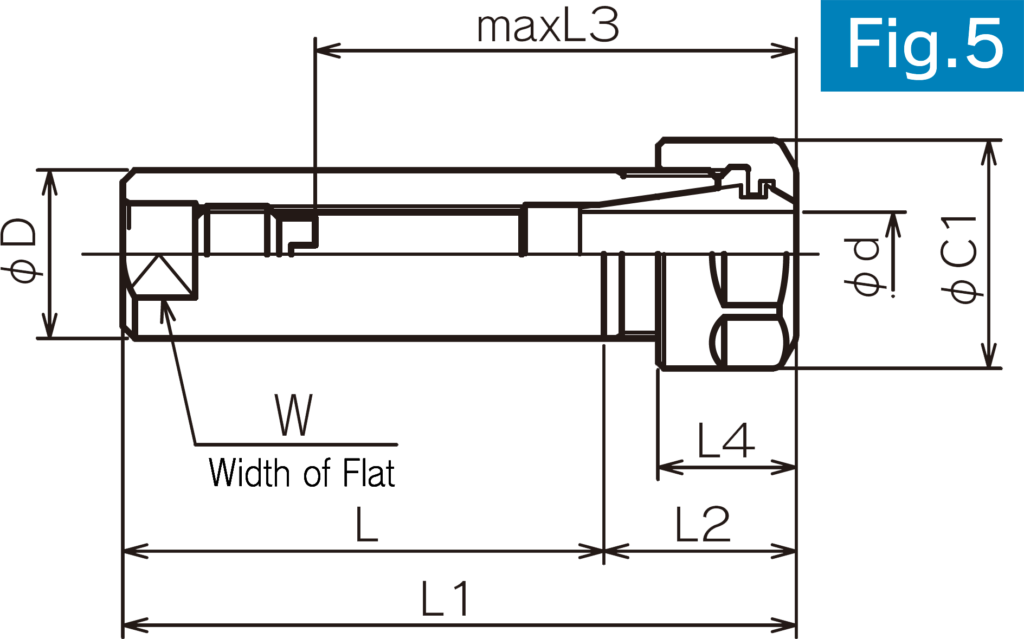

NA-R/ SR type (Fig.1/ 5)

・This type is suitable for high speed machining since is highly well-balanced.

・This type is made to order.

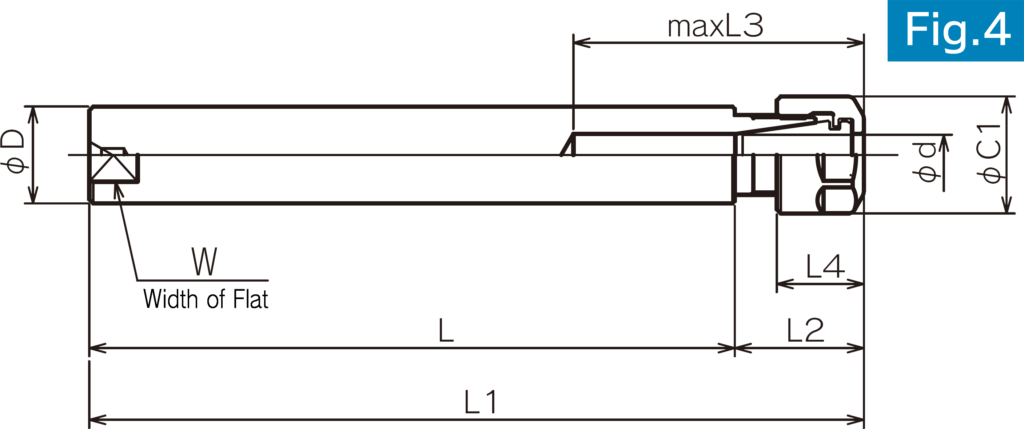

NA-M (Fig.4)

・This type significantly prevents tool interference since external dimension is smaller than that of S type.

Notice

A special holder is essential since size of M screw is different.

NA-F type (Fig.6)

・This type is thinner than the other types.

Notice

Special holder is essential since size of M screw is different.

| CODE | Fig | D | L | M | H | Collet | Holder Type | Wrench |

| NA11 | 1 | 23 | 11.5 | M14×0.75 | – | AR11-d | -ECH 7 | FK-3 |

| NA11R | ||||||||

| NA16 | 32 | 17 | M22×1.5 | AR16-d | -ECH10 | FK-4 | ||

| NA16R | ||||||||

| NA20 | 36 | 19 | M25×1.5 | AR20-d | -ECH13 | FK-5 | ||

| NA20R | ||||||||

| NA25 | 43 | 20 | M32×1.5 | AR25-d | -ECH16 | FK-6 | ||

| NA25R | ||||||||

| NA32 | 51 | 23 | M40×1.5 | AR32-d | -ECH20 | FK-8 | ||

| NA32R | ||||||||

| NA40 | 63 | 25 | M50×1.5 | AR40-d | -ECH26 | FK-9 | ||

| NA50 | 80 | 35 | M64×2.0 | AR50-d | -ECH34 | FK-11 | ||

| NA 8S | 2 | 14.5 | 10.8 | M10×0.75 | 13 | AR 8-d | -ECH5S | SP-13 |

| NA11S | 19 | 11.5 | M14×0.75 | 17 | AR11-d | -ECH7 | SP-17A | |

| NA11SR | 5 | |||||||

| NA16S | 2 | 28 | 17 | M22×1.5 | 25 | AR16-d | -ECH10 | SP-25 |

| NA16SR | 5 | |||||||

| NA20S | 2 | 34 | 19 | M25×1.5 | 30 | AR20-d | -ECH13 | SP-30 |

| NA20SR | 5 | |||||||

| NA25S | 3 | 42 | 20 | M32×1.5 | – | AR25-d | -ECH16 | FK-6 |

| NA32S | 50 | 23 | M40×1.5 | AR32-d | -ECH20 | FK-7 | ||

| NA 8M | 4 | 12 | 10.8 | M10×0.75 | AR 8-d | -ECH5s | AE-8M | |

| NA11M | 16 | 12 | M13×0.75 | AR11-d | – | AE-11M | ||

| NA16M | 22 | 18 | M19×1.0 | AR16-d | AE-16M | |||

| NA20M | 28 | 19 | M24×1.0 | AR20-d | AE-20M | |||

| NA 8MR | 5 | 12 | 10.8 | M10×0.75 | 11 | AR 8-d | SP-11 | |

| NA11MR | 16 | 12 | M13×0.75 | 15 | AR11-d | SP-16 | ||

| NA16MR | 22 | 18 | M19×1.0 | 20 | AR16-d | SP-20 | ||

| NA11F | 6 | 23 | 11 | M15×1.0 | AR11-d | FK-3 | ||

| NA16F | 30 | 15 | M22×1.0 | AR16-d | FK-4 | |||

| NA20F | 35 | 17 | M25×1.0 | AR20-d | FK-5 | |||

| NA25F | 42 | 18 | M32×1.0 | AR25-d | FK-6 | |||

| NA32F | 50 | 19 | M40×1.0 | AR32-d | FK-7 |

Notice

・NA-R/ SR/ MR is made to order.

・We offer special nuts, please feel free to order.

-

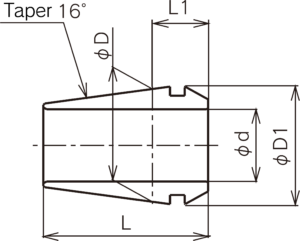

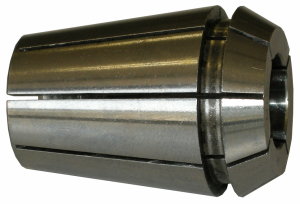

AR collet chuck

・European standard 16°tapered (DIN6499/ ISO15488) collet

We offer durable products with high precision made with highly evaluated technique as a collet chuck manufacturer.

・Used by domestic Major Machine Builders as standard.

Drill collets for Swiss type NC lathes. Collets for rotary tool. Collet chucks and tap collets for rotary tool of turning-mill centers.

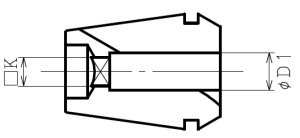

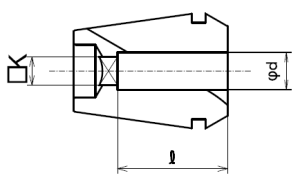

AR collets: Specification

| Φd | |||||||

| Code | ID | Gripping Range | D | D1 | L | L1 | Holder |

| AR 8-d | 0.5~5 | 0.2~0.5 | 8 | 8.4 | 13.6 | 4.6 | ECH5S |

| AR11-d | 1 ~ 7 | 0.5 | 11 | 11.5 | 18 | 6.5 | ECH 7 |

| AR16-d | 1 ~10 | 0.5~1.0 | 16 | 17 | 27 | 10 | ECH10 |

| AR20-d | 1 ~13 (14) | 20 | 21 | 31 | 11 | ECH13 | |

| AR25-d | 1 ~16 | 25 | 26 | 35 | 11.5 | ECH16 | |

| AR32-d | 3~20 | 32 | 33 | 40 | 12.5 | ECH20 | |

| AR40-d | 4~26 | 1 | 40 | 41 | 46 | 14.5 | ECH26 |

| AR50-d | 6~34 | 1~2 | 50 | 52 | 60 | 21.0 | ECH34 |

AR collets: Size・Gripping range

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notice

Tool would not be installed to the end of tool holder when you use AR20-14.

-

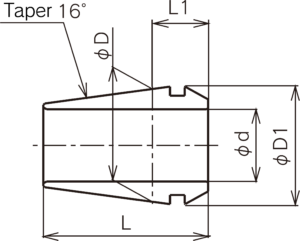

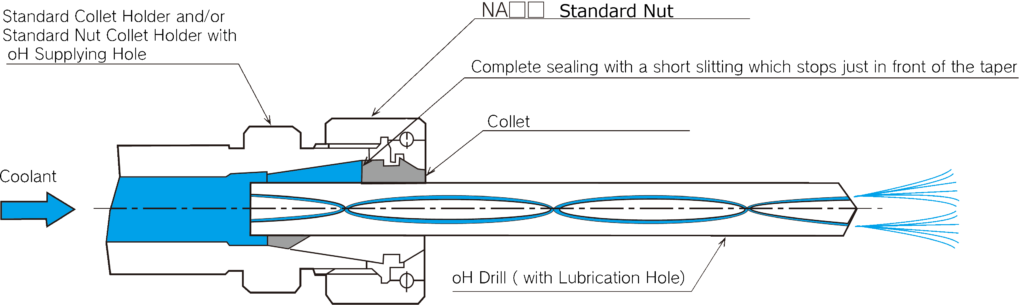

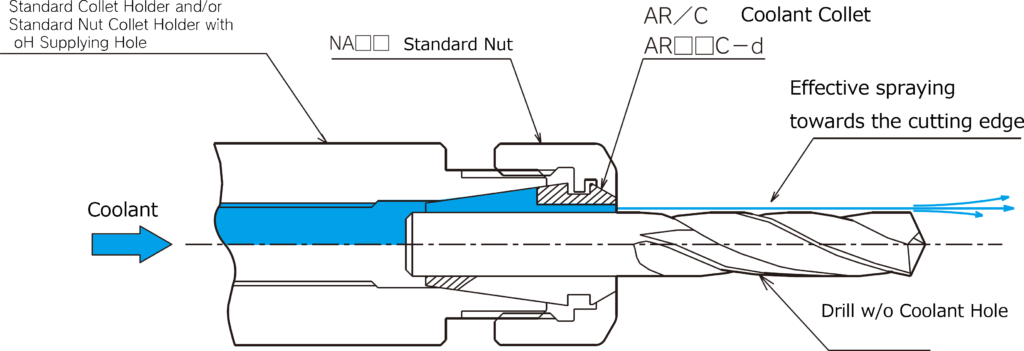

AR/OH coolant collet

AR/OH coolant collet is a new liquid tight collet chuck which is able to seal high pressure coolant and has gripping range from 0.1mm to 0.5mm realized owing to special slits.

This collet can stand water pressure of 7MPa.

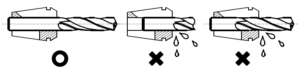

Correct usage

We offer various size from φ3 to φ34, please choose appropriate one according to the purposes.

| Φd | ||||||

| CODE | ID | Gripping Range | ΦD | ΦD1 | L | L1 |

| AR11OH-d | 2~7 | 0.1 | 11 | 11.5 | 18 | 6.5 |

| AR16OH-d | 2~6 | 0.1 | 16 | 17 | 27 | 10 |

| 6~10 | 0.5 | |||||

| AR20OH-d | 3~6 | 0.1 | 20 | 31 | 31 | 11 |

| 6~13 | 0.5 | |||||

| AR25OH-d | 3~6 | 0.1 | 25 | 35 | 35 | 11.5 |

| 6~16 | 0.5 | |||||

| AR32OH-d | 3~8 | 0.1 | 32 | 40 | 40 | 12.5 |

| 8~20 | 0.5 | |||||

| AR40OH-d | 10~26 | 0.5 | 40 | 46 | 46 | 14.5 |

| AR50OH-d | 16~34 | 0.5 | 50 | 60 | 60 | 21.0 |

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notice

1, Collets in size which is not shown in the above table is made to order.

2, It is compatible with oil hole (OH) type drill.

3, Please insert a drill to the end of collets.

4, Shape of nonstandard products differs from that of standard products.

5, There is a possibility of leaking coolant if you clamp a drill which is beyond nominal number (-0.1 to 0.5mm) of each collets.

6, Sealing function does not work if you use drill with flattened straight shank.

7, AR50OH is made to order.

-

AR/GB tap collet

There is a square rotation stopper inside. This stopper prevents rotation during the machining and assures certain tapping.

Size

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notice

1, This table is conforming to a tap with JIS standard shank.

Please contact us about a tap with ANSI, DIN, and ISO standard shank or a tap in size which is not shown is the table above.

2, Tap collet for each tap size is necessary.

3, You can attach a tap collet to ECH type collet holder if the machine uses synchro tapping.

4, Core deflection accuracy is conforming to S grade.

5, AR50 is made to order.

-

AR/GH coolant tap collet

This type is the collet chuck for oil hole tapping. AR/GH has better water tightening ability than AR/GB tap collet (for synchro tap machining) and can stand water pressure of 7MPa. This collet help prolong tool’s life and compatible with tapping (using long shank tap) for deep hole.

Correct method for use

Size

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notice

1, This table is conforming to a tap with JIS standard shank.

Please contact us about a tap with ANSI, DIN, and ISO standard shank or a tap in size which is not shown is the table above.

2, Tap collet for each tap size is necessary.

3, You can attach a tap collet to ECH type collet holder if the machine uses synchro tapping.

4, Core deflection accuracy is conforming to S grade.

5, Please insert tap tooling to the end of the collet on order to prevent leaking.

-

AR/C tap collet

AR/C coolant collet is a new liquid tight collet chuck which is able to seal high pressure coolant and has gripping range from 0.1mm to 0.5mm realized with special slits.

This collet can stand water pressure of 7MPa.

・Compatible with high pressure coolant. Every structure except for coolant slit of this type can seal 7MPa of water pressure.

・It is possible to easily remove chip from edge by spraying coolant toward that part.

・This type is beneficial for small diameter deep holes that cannot be processed by oil hole drill.

・Compatible with water-soluble coolant as standard. It is possible to make it compatible with oil based coolant.

・It is also suitable for semi-dry machining (mist).

Size・Gripping Range (made to order)

| d | ||||||

| CODE | ID | Gripping Range | D | D1 | L | L1 |

| AR 8C-d | 2~4 | just ID size | 8 | 8.4 | 13.6 | 4.6 |

| AR11C-d | 3~7 | 0.1 | 11 | 11.5 | 18 | 6.5 |

| AR16C-d | 3~5.9 | 0.1 | 16 | 17 | 27 | 10 |

| 6~10 | 0.5 | |||||

| AR20C-d | 5~5.9 | 0.1 | 20 | 21 | 31 | 11 |

| 6~13 | 0.5 | |||||

| AR25C-d | 6~16 | 0.5 | 25 | 26 | 35 | 11.5 |

| AR32C-d | 8~20 | 0.5 | 32 | 33 | 40 | 12.5 |

Notice

1, This collet is compatible with water-soluble coolant. We offer ones compatible with oil based coolant if you need.

2, Please specify the grade and type of coolant you need when you order. Coolant type: (C or CY) Grade: (S, A, AA, AAA)

Example, Grade S φ6 collet compatible with water-soluble coolant: AR16C-6

Grade A φ6 collet compatible with oil based coolant: AR16CY-6AA

3, Please insert a drill to the end of the collet.

4, There is a possibility of leaking coolant if you clamp a drill which is beyond nominal number (-0.1 to 0.5mm) of each collets.

5, Sealing function does not work if you use flattened straight shank drill.

6, Internal shape differs depend on φd

-

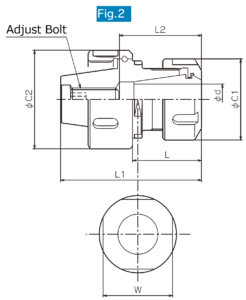

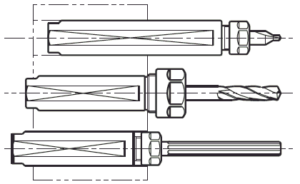

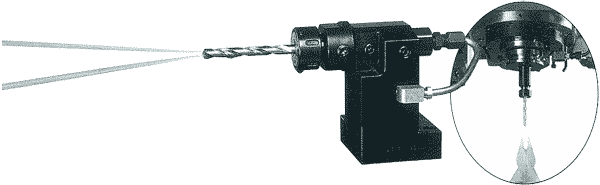

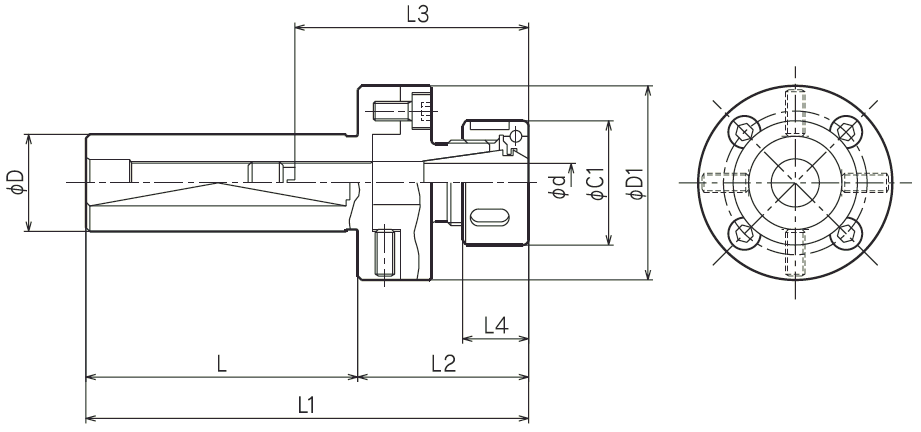

Tool change head

Tool change head allow you to reduce work interference, change collet size, and adjust projection length by simply replacing a standard nut with this accessory without changing turning tools, spindles, and collet holders.

Size

| CODE | Fig | Base Holder Code | d | L | L1 | L2 | C1 | C2 | W | Collet Chuck | Wrench | ||

| Base Side | Fixture for W | Head Side | |||||||||||

| TCR16-ECH 7-22 | 1 | ECH10 | 0.5~ 7 | 22 | 46 | 25 | 19 | 32 | 17 | AR11-d | FK-4 | SP-17A | SP-17A |

| TCR20-ECH10-30 | ECH13 | 0.5~10 | 30 | 60 | 35 | 28 | 36 | 25 | AR16-d | FK-5 | SP-25 | SP-25 | |

| TCR25-ECH13-32 | ECH16 | 0.5~13 | 32 | 65 | 40 | 34 | 43 | 30 | AR20-d | FK-6 | SP-30 | SP-30 | |

| TCR32-ECH16-35 | 2 | ECH20 | 0.5~16 | 35 | 72 | 45 | 42 | 51 | 36 | AR25-d | FK-8 | SP-36 | FK-6 |

| TCR40-ECH20-37 | ECH26 | 2.5~10 | 37 | 82 | 50 | 50 | 63 | 46 | AR32-d | FK-9 | SP-46 | FK-7 | |

Notice

1, The holder is used in combination with a collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, We offer special shank, please feel free to order.

-

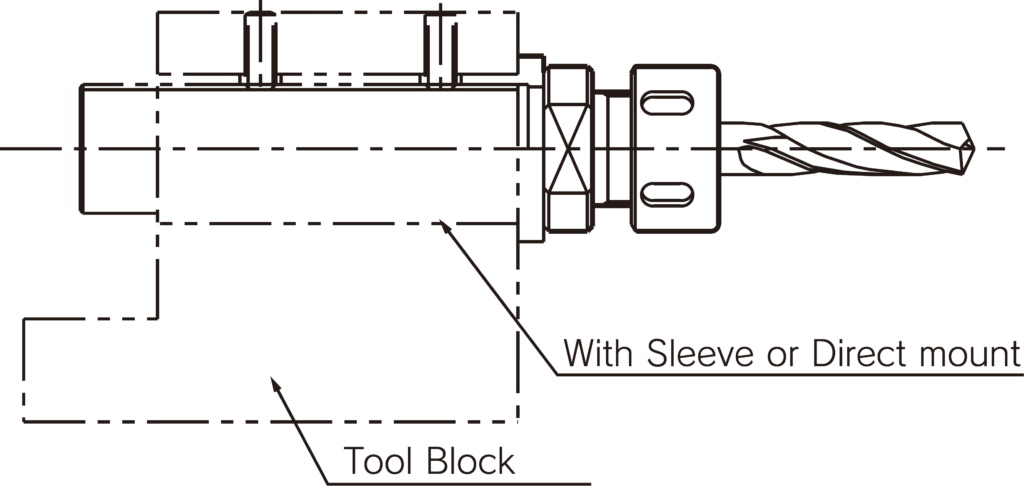

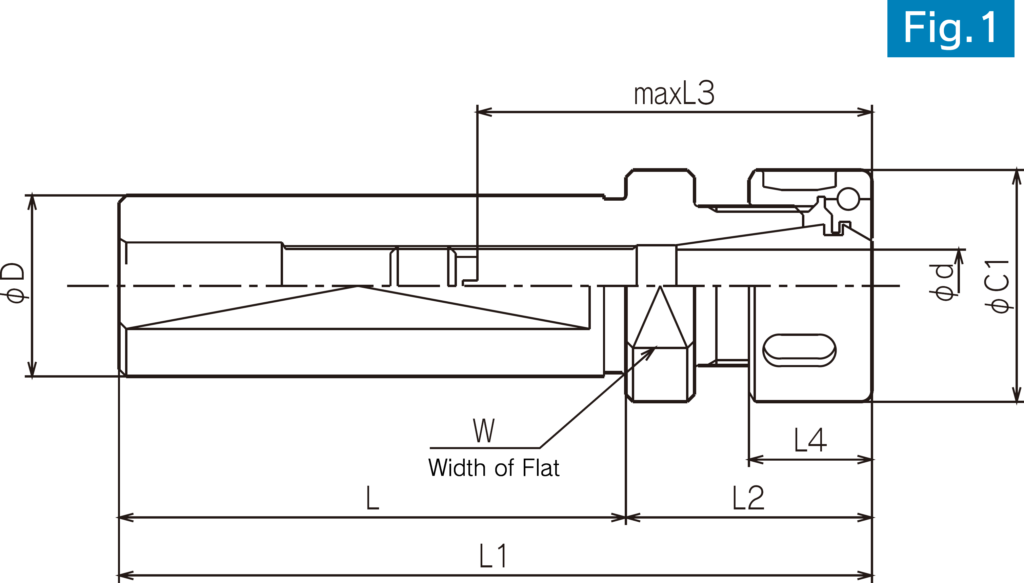

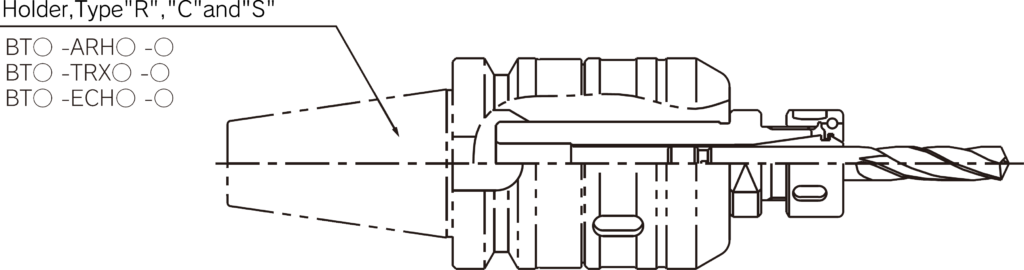

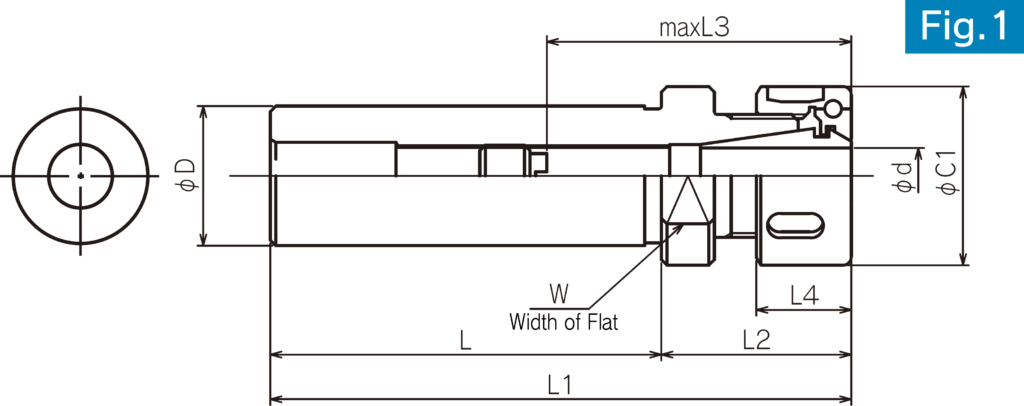

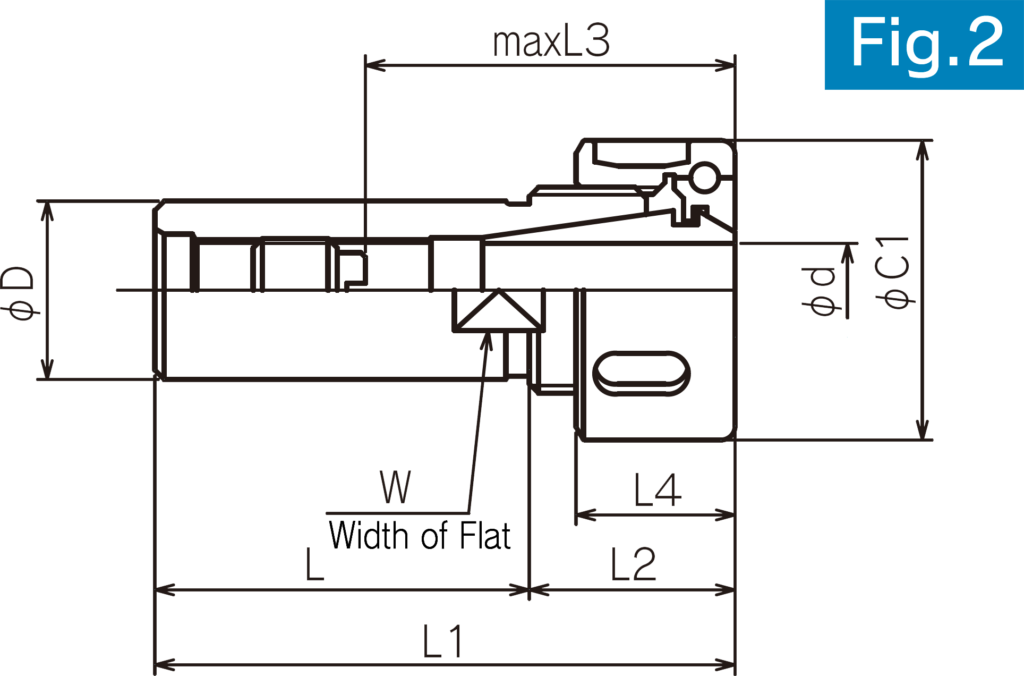

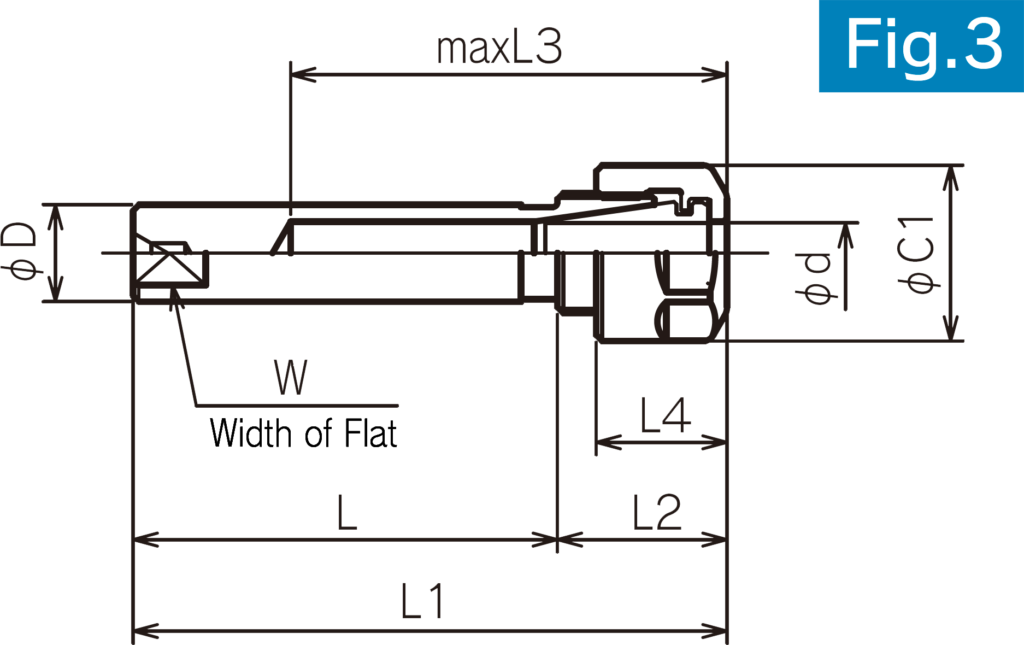

Collet holder

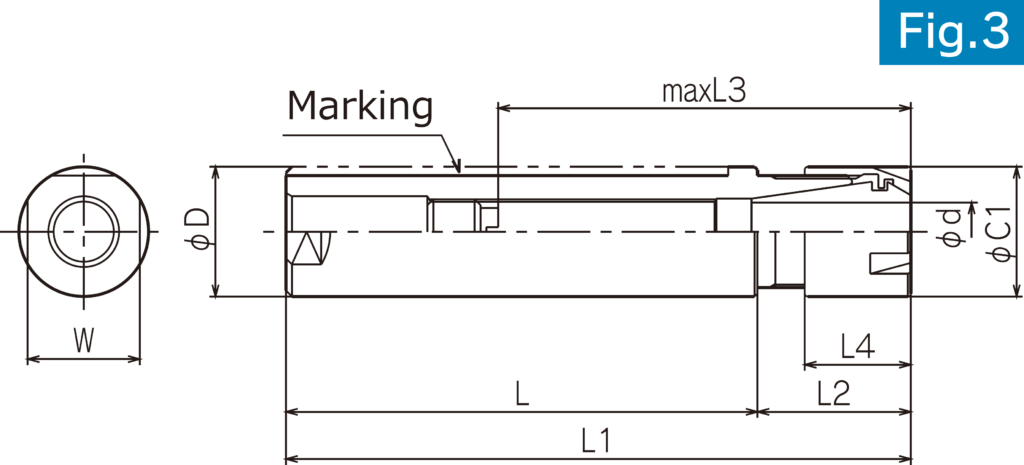

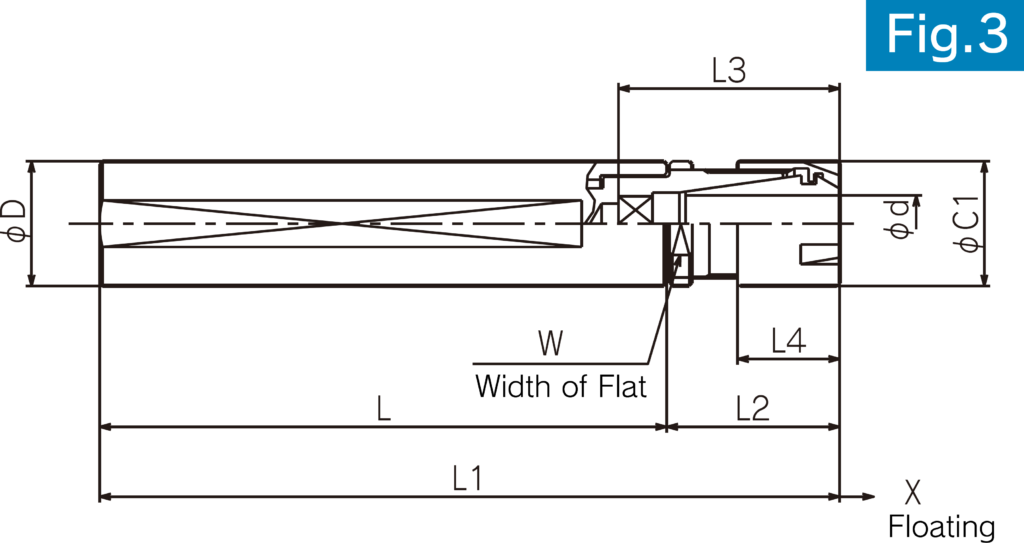

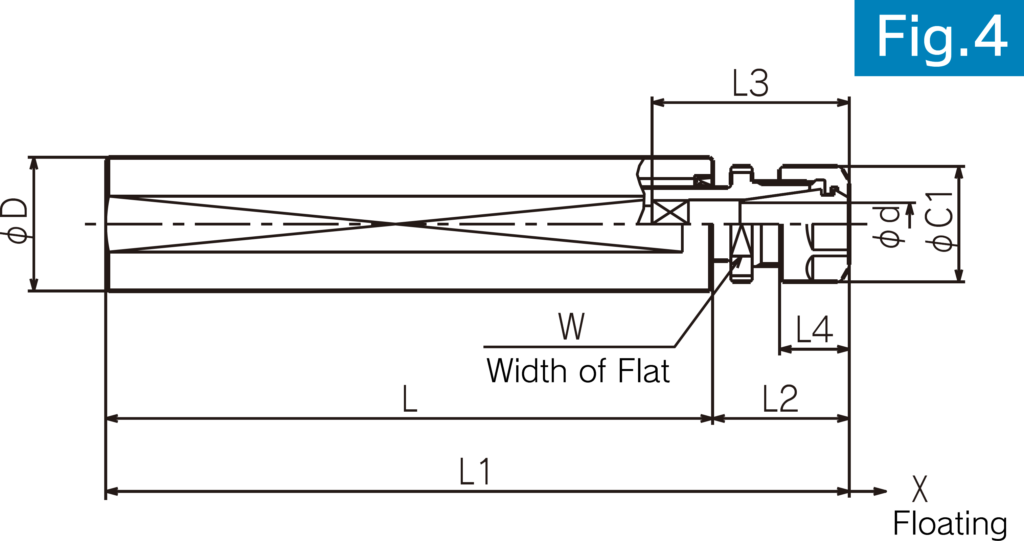

Holder (Milled shank)

Holder for NC lathes which has milled shank.

Example (1) Usage example for a NC lathe.

Please select from Fig.1 and 2.

Example (1) Usage example for a machining center,

Please select from Fig.1 which has milled face on D2 shank.

| CODE | d | D | Fig. | L | L1 | L2 | max L3 | Nut | W | Option | |||

| C1 | L4 | Collet Chuck | Wrench | ||||||||||

| SSH16-ECH 7- 32 | 0.5~7 | 16 | 2 | 32 | 48 | 16 | 35 | 23 | 11.5 | 14 | AR11-d | FK-3 | |

| SSH16-ECH 7- 70 | 1 | 70 | 94 | 24 | 55 | 19 | |||||||

| ◯ | SSH20-ECH 7- 45 | 20 | 2 | 45 | 61 | 16 | 45 | ||||||

| ◯ | SSH20-ECH 7- 70 | 1 | 70 | 94 | 24 | 55 | |||||||

| SSH20-ECH 7-105 | 105 | 129 | 70 | ||||||||||

| ◯ | SSH20-ECH10- 40 | 0.5~10 | 2 | 40 | 63 | 23 | 45 | 32 | 17 | 17 | AR16-d | FK-4 | |

| ◯ | SSH20-ECH10- 70 | 1 | 70 | 105 | 35 | 70 | 24 | ||||||

| SSH20-ECH10-105 | 105 | 140 | 80 | ||||||||||

| ◯ | SSH20-ECH13- 70 | 1~13 | 70 | 106 | 36 | 75 | 36 | 19 | 27 | AR20-d | FK-5 | ||

| ◯ | SSH25-ECH 7- 62 | 0.5~7 | 25 | 2 | 62 | 86 | 24 | 55 | 23 | 11.5 | 19 | AR11-d | FK-3 |

| ◯ | SSH25-ECH10- 70 | 0.5~10 | 1 | 70 | 105 | 35 | 70 | 32 | 17 | 27 | AR16-d | FK-4 | |

| ◯ | SSH25-ECH10-105 | 105 | 140 | 80 | |||||||||

| ◯ | SSH25-ECH13- 70 | 1~13 | 70 | 106 | 36 | 75 | 36 | 19 | AR20-d | FK-5 | |||

| ◯ | SSH25-ECH16- 70 | 1~16 | 110 | 40 | 80 | 43 | 20 | 36 | AR25-d | FK-6 | |||

| ◯ | SSH32-ECH13- 80 | 1~13 | 32 | 80 | 116 | 36 | 75 | 36 | 19 | 32 | AR20-d | FK-5 | |

| ◯ | SSH32-ECH16- 80 | 1~16 | 120 | 40 | 80 | 43 | 20 | 36 | AR25-d | FK-6 | |||

| ◯ | SSH32-ECH20- 80 | 2~20 | 128 | 48 | 100 | 51 | 23 | 46 | AR32-d | FK-8 | |||

| SSH40-ECH20- 80 | 40 | ||||||||||||

| SSH40-ECH20-110 | 110 | 158 | |||||||||||

Notes

1, Holders are used in combination, please order chuck collets separately.

2, A spanner is not supplied, please order it separately.

3, S type nuts can be used in combination, please replace other nut with S type one in case of tool interference.

4, Products with ○ oat CODE column are standard stock.

5, We will produce special shank in size not shown in the above tables, please feel free to ask.

Holder (Cylindrical shank)

Cylindrical shank style holder for machining center etc.

Usage example: Machining center

Example: Use in combination with a milling chuck for machining center.

Collet holder (metric, ) specification・size

| CODE | d | D | Fig. | L | L1 | L2 | max L3 | Nut | W | Option | |||

| C1 | L4 | Collet Chuck | Wrench | ||||||||||

| SS 8-ECH5S- 35 | 0.3~5 | 8 | 3 | 35 | 49 | 14 | 36 | 14.5 | 10.8 | 6 | AR 8-d | SP-13 | |

| SS12-ECH5S- 80 | 12 | 4 | 80 | 96 | 16 | ※(7) | 10 | ||||||

| SS16-ECH 7- 40 | 0.5~7 | 16 | 2 | 40 | 56 | 40 | 23 | 11.5 | 14 | AR11-d | FK-3 | ||

| SS16-ECH 7- 70 | 1 | 70 | 94 | 24 | 55 | 19 | |||||||

| SS20-ECH 7- 45 | 20 | 2 | 45 | 61 | 16 | 45 | 17 | ||||||

| ◯ | SS25-ECH10- 70 | 0.5~10 | 25 | 1 | 70 | 105 | 35 | 70 | 32 | 17 | 27 | AR16-d | FK-4 |

| SS25-ECH10-105 | 150 | 185 | 53 | ||||||||||

| ◯ | SS25-ECH13- 70 | 1~13 | 70 | 106 | 36 | 75 | 36 | 19 | AR20-d | FK-5 | |||

| SS25-ECH13-150 | 150 | 172 | 22 | 55 | 24 | ||||||||

| SS25-ECH13-200 | 200 | 222 | |||||||||||

| SS25-ECH16- 70 | 1~16 | 70 | 110 | 40 | 80 | 43 | 20 | 36 | AR25-d | FK-6 | |||

| SS25-ECH16-150 | 150 | 190 | 67 | 27 | |||||||||

| SS25-ECH16-200 | 200 | 240 | |||||||||||

| SS32-ECH10- 80 | 0.5~10 | 32 | 80 | 119 | 39 | 70 | 32 | 17 | 32 | AR16-d | FK-4 | ||

| SSH32-ECH13- 80 | 1~13 | 116 | 36 | 75 | 36 | 19 | AR20-d | FK-5 | |||||

| SS32-ECH16- 80 | 1~16 | 120 | 40 | 80 | 43 | 20 | 36 | AR25-d | FK-6 | ||||

| SS32-ECH16-150 | 150 | 190 | 67 | ||||||||||

| SS32-ECH20- 80 | 2~20 | 80 | 128 | 48 | 100 | 51 | 23 | 46 | AR32-d | FK-8 | |||

| SS40-ECH20-110 | 40 | 110 | 158 | ||||||||||

| SS40-ECH20-200 | 200 | 226 | 26 | 36 | |||||||||

| SS40-ECH20-300 | 300 | 326 | |||||||||||

Notice

1, Holders are used in combination with chuck collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, S type nuts can be used in combination, please replace other nut with S type one in case of tool interference.

4, Products with ○ at CODE column are standard stock.

5, We will produce special shank in size not shown in the above tables, please feel free to ask.

6, CODE No.5S comes with a S nut.

7, There is no adjustment structure.

8, ECH5S is used in combination with different type of nuts.

-

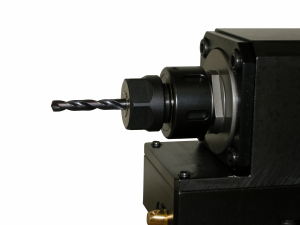

Short nose collet holder

・This is small and short holder suitable for Swiss type and くし刃型 lathes.

・S nut, which diameter is relatively small comes with the holder.

・This tool has the shortest projecting length among our products.

・This holder makes it possible to use nicemill on a machine with narrow tooling zone.

Short nose collet holder (Metric) Specification・size

| CODE | d | D | FIG | L | L1 | L2 | max L3 | Nut | W | Option | |||

| C1 | L4 | Collet Chuck | Wrench | ||||||||||

| SSH12-ECH 5S- 70 | 0.3~5 | 12 | 1 | 70 | 86 | 16 | 36 | 14.5 | 10.8 | 10 | AR 8-d | SP-13 | |

| SSH16-ECH 5S- 70 | 16 | ※(6) | 14 | ||||||||||

| SSH16-ECH 7S- 35 | 0.5~7 | 35 | 51 | 35 | 19 | 11.5 | AR11-d | SP-17A | |||||

| SSH16-ECH 7S- 70 | 70 | 86 | 55 | ||||||||||

| SSH16-ECH10S- 35 | 0.5~10 | 2 | 35 | 70 | 35 | 43 | 28 | 17 | 19 | AR16-d | SP-25 | ||

| SSH16-ECH10S- 70 | 70 | 105 | |||||||||||

| ◯ | SSH20-ECH 7S- 40 | 0.5~7 | 20 | 1 | 40 | 56 | 16 | 40 | 19 | 11.5 | 17 | AR11-d | SP-25 |

| ◯ | SSH20-ECH 7S- 70 | 70 | 86 | 55 | |||||||||

| SSH20-ECH 7S-105 | 105 | 121 | 70 | ||||||||||

| ◯ | SSH20-ECH10S- 40 | 0.5~10 | 40 | 62 | 22 | 45 | 28 | 17 | AR16-d | SP-25 | |||

| ◯ | SSH20-ECH10S-70 | 70 | 92 | 70 | |||||||||

| SSH20-ECH10S-105 | 105 | 127 | 80 | ||||||||||

| SSH20-ECH13S- 40 | 1~13 | 2 | 40 | 70 | 30 | 55 ※(6) | 34 | 19 | 22 | AR20-d | SP-30 | ||

| SSH20-ECH13S- 70 | 70 | 100 | 75 | ||||||||||

| SSH22-ECH10MS- 38 | 0.5~10 | 22 | 3 | 38 | 64 | 26 | 52 | 22 | 18 | 19 | AR16-d | AE-16M | |

| SSH22-ECH10MS- 70 | 70 | 96 | 70 | ||||||||||

| ◯ | SSH22-ECH10MS- 80 | 80 | 106 | ||||||||||

| ◯ | SSH22-ECH10MS-105 | 105 | 131 | 80 | |||||||||

| ◯ | SSH25-ECH 7S- 62 | 0.5~7 | 25 | 1 | 62 | 78 | 16 | 55 | 19 | 11.5 | – | AR11-d | SP-17A |

| ◯ | SSH25-ECH 7S- 70 | 70 | 86 | 22 | |||||||||

| ◯ | SSH25-ECH 7S- 85 | 85 | 101 | – | |||||||||

| SSH25-ECH 7S-105 | 105 | 121 | 70 | 22 | |||||||||

| ◯ | SSH25-ECH10S- 40 | 0.5~10 | 40 | 63 | 23 | 45 | 28 | 17 | AR16-d | SP-25 | |||

| ◯ | SSH25-ECH10S- 50 | 50 | 73 | 55 | |||||||||

| ◯ | SSH25-ECH10S-70 | 70 | 93 | 70 | |||||||||

| SSH25-ECH10S-105 | 105 | 128 | 80 | ||||||||||

| ◯ | SSH25-ECH13S- 50 | 1~13 | 50 | 74 | 24 | 55 | 34 | 19 | AR20-d | SP-30 | |||

| ◯ | SSH25-ECH13S- 70 | 70 | 94 | 75 | |||||||||

| ◯ | SSH25-ECH16S- 50 | 1~16 | 2 | 50 | 85 | 35 | 52 | 42 | 20 | 27 | AR25-d | FK-6 | |

| SSH32-ECH13S- 60 | 1~13 | 32 | 1 | 60 | 86 | 26 | 65 | 34 | 19 | AR20-d | SP-30 | ||

| SSH32-ECH16S- 60 | 1~16 | 87 | 27 | 42 | 20 | AR25-d | FK-6 | ||||||

Short nose collet holder (Inch) Specification・size

| CODE | d | D | FIG | L | L1 | L2 | max L3 | Nut | W | Option | |||

| C1 | L4 | Collet | Wrench | ||||||||||

| SSH5/8-ECH 7S- 70 | 0.5~7 | 15.875 | 1 | 70 | 86 | 16 | 55 | 19 | 11.5 | 14 | AR11-d | SP-17A | |

| SSH5/8-ECH10S- 70 | 0.5~10 | 2 | 105 | 35 | 43 | 28 | 17 | 19 | AR16-d | SP-25 | |||

| SSH3/4-ECH 7S- 40 | 0.5~7 | 19.05 | 1 | 40 | 56 | 16 | 40 | 19 | 11.5 | 17 | AR11-d | SP-17A | |

| ◯ | SSH3/4-ECH 7S- 70 | 70 | 86 | 55 | |||||||||

| ◯ | SSH3/4-ECH 7S-105 | 105 | 121 | 70 | |||||||||

| ◯ | SSH3/4-ECH 7S-120 | 120 | 136 | ||||||||||

| SSH3/4-ECH10S- 40 | 0.5~10 | 40 | 62 | 22 | 45 | 28 | 17 | AR16-d | SP-25 | ||||

| ◯ | SSH3/4-ECH10S- 70 | 70 | 92 | 70 | |||||||||

| ◯ | SSH3/4-ECH10S-105 | 105 | 127 | 80 | |||||||||

| SSH3/4-ECH10S-120 | 120 | 142 | |||||||||||

| SSH3/4-ECH13S- 40 | 1~13 | 2 | 40 | 70 | 30 | 55 ※(6) | 34 | 19 | 22 | AR20-d | SP-30 | ||

| ◯ | SSH 1 -ECH 7S- 70 | 0.5~7 | 25.4 | 1 | 70 | 86 | 16 | 55 | 19 | 11.5 | AR11-d | SP-17A | |

| SSH 1 -ECH 7S-105 | 105 | 121 | 70 | ||||||||||

| SSH 1 -ECH10S- 50 | 0.5~10 | 50 | 73 | 23 | 55 | 28 | 17 | AR16-d | SP-25 | ||||

| ◯ | SSH 1 -ECH10S- 70 | 70 | 93 | 70 | |||||||||

| SSH 1 -ECH10S-105 | 105 | 128 | 80 | ||||||||||

| SSH 1 -ECH13S- 50 | 1~13 | 50 | 74 | 24 | 55 | 34 | 19 | AR20-d | SP-30 | ||||

| SSH 1 -ECH13S- 70 | 70 | 94 | 75 | ||||||||||

| SSH 1 -ECH16S- 50 | 1~16 | 2 | 50 | 85 | 35 | 52 | 42 | 20 | 27 | AR25-d | FK-6 | ||

Notice

1, Holders are used in combination with chuck collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, In case gripping strength is not enough, a S nut can be replaced with a standard nut.

4, Products with ○ at CODE column are standard stock.

5, We will produce special shank in size not shown in the above tables, please feel free to ask.

6, There is no adjustment structure.

7, ECH16S is used in combination with different type of nuts.

-

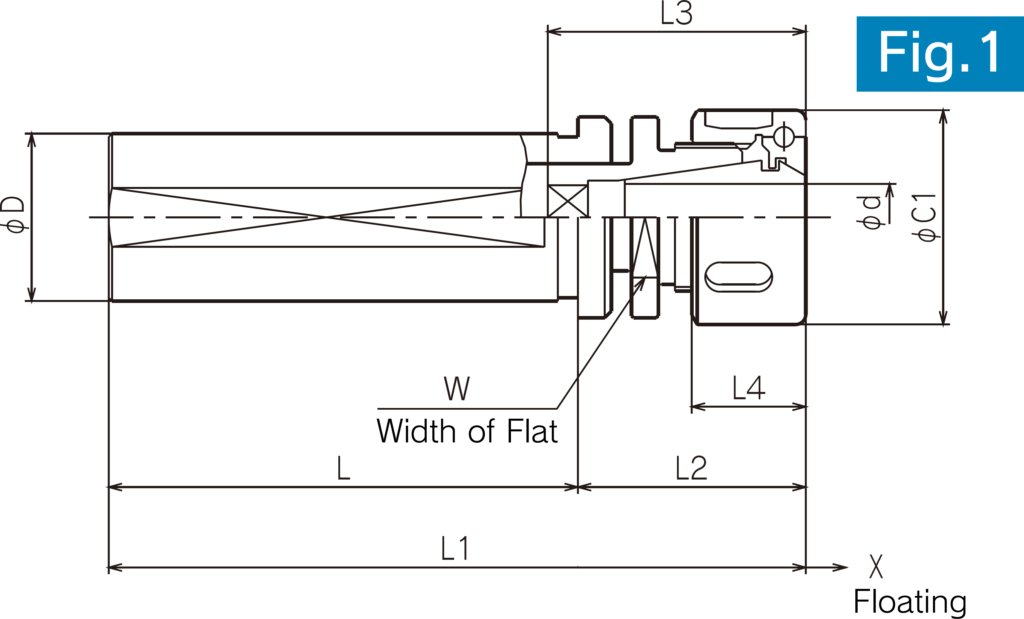

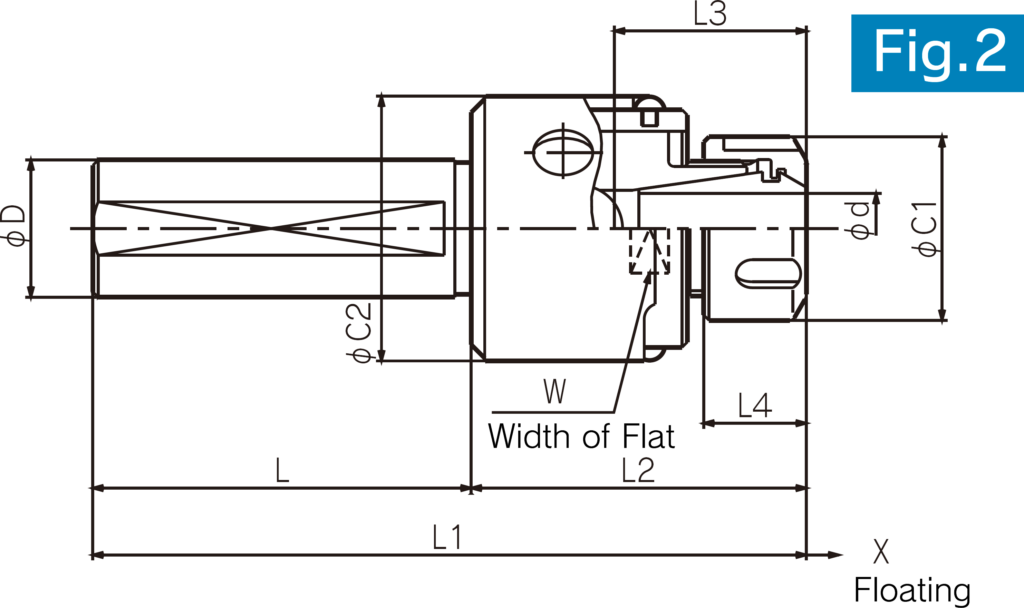

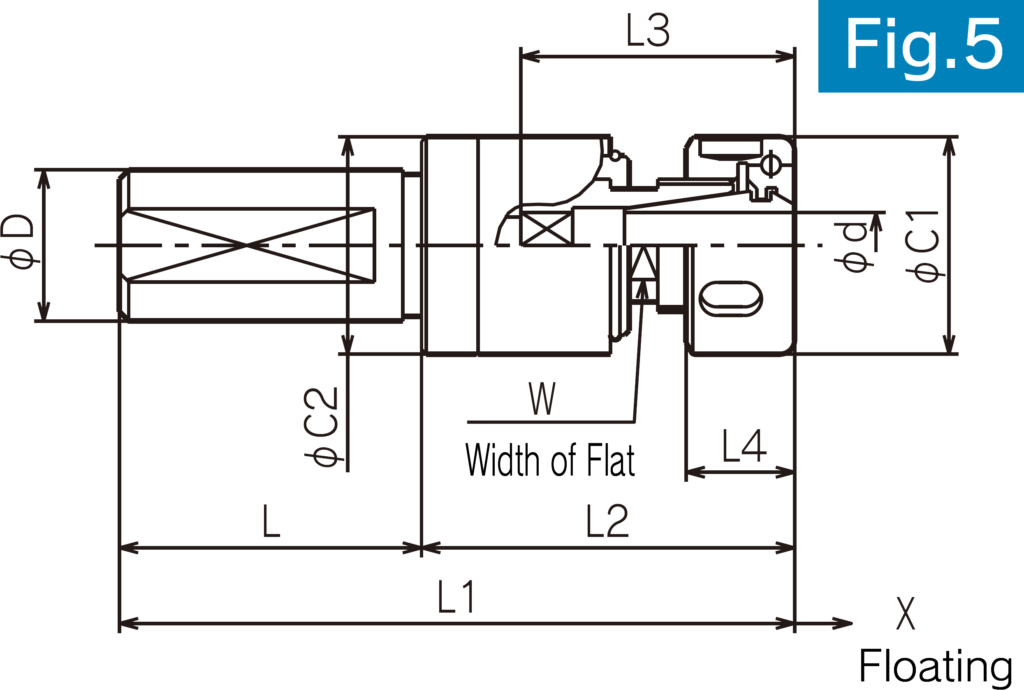

Tap holder (Axial direction float mechanism)

This is the tap holder for NC lathes that can correct screw pitch error by floating movement of the spindle.

Usage example on a NC lathe.

Specification・Size

| CODE | Tap Size | D | FIG | L | L1 | L2 | L3 | Nut | C2 | W | Floating X | Option | |||

| C1 | L4 | Collet Chuck | Wrench | ||||||||||||

| SST16-ECH 7 – 32 | ~M10 | 16 | 5 | 32 | 71.5 | 39.5 | 29 | 23 | 11.5 | 23 | 12 | 5 | AR11-d | FK-3 | |

| ◯ | SST20-ECH 7 – 40 | 20 | 1 | 40 | 66 | 26 | 29.5 | – | |||||||

| ◯ | SST20-ECH 7 – 70 | 70 | 97.5 | 27.5 | 32.5 | 17 | 8 | ||||||||

| SST20-ECH 7S – 70 | 4 | 92.5 | 22.5 | 19 | SP-17A | ||||||||||

| ◯ | SST22-ECH10MS- 90 | ~M12 | 22 | 3 | 90 | 120.5 | 30.5 | 39 | 22 | 18 | 19 | 10 | AR16-d | AE-16M | |

| SST22-ECH10MS-100 | 100 | 130.5 | |||||||||||||

| SST22-ECH 7S -100 | ~M10 | 4 | 122.5 | 22.5 | 32.5 | 19 | 11.5 | 17 | AR11-d | SP-17A | |||||

| SST25-ECH 7 – 70 | 25 | 1 | 70 | 97.5 | 27.5 | 23 | 8 | FK-3 | |||||||

| ◯ | SST25-ECH10 – 70 | ~M12 | 104.5 | 34.5 | 39 | 32 | 17 | 24 | AR16-d | FK-4 | |||||

| ◯ | SST25-ECT13 – 70 | M10~M16 | 2 | 132 | 62 | 40.5 | 34 | 19 | 49 | 32 | 12 | AR20-d | SP-30 | ||

| SST25-ECT16 – 70 | M14~M20 | 135 | 65 | 45 | 42 | 20 | 57 | 38 | AR25-d | FK-6 | |||||

| SST32-ECT13 – 80 | M10~M16 | 32 | 80 | 142 | 62 | 40.5 | 34 | 19 | 49 | 32 | AR20-d | SP-30 | |||

| SST32-ECT16 – 80 | M14~M20 | 145 | 65 | 45 | 42 | 20 | 57 | 38 | AR25-d | FK-6 | |||||

| SST3/4-ECH 7S – 46 | ~M10 | 19.05 | 4 | 46 | 66 | 20 | 29.5 | 19 | 11.5 | – | 12 | 5 | AR11-d | SP-17A | |

| ◯ | SST3/4-ECH 7S – 70 | 70 | 92.5 | 22.5 | 32.5 | 8 | |||||||||

| SST3/4-ECH 7S -105 | 105 | 127.5 | 17 | ||||||||||||

| SST 1 -ECH10 – 70 | ~M12 | 25.4 | 1 | 70 | 104.5 | 34.5 | 39 | 32 | 17 | 24 | AR16-d | FK-4 | |||

Notice

1, The holder is used in combination with a coolant collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, We offer special shank size which is not shown on the above table as well.

4, There is a 5.5 mm square hole on ECH7 and 6.5 mm square hole on ECH10.

5, ECT13 and ECT16 chuck square corner of a tap. (Fig.2)

6, Please use PF-PT tap in combination with a long shank tap.

7, ECH7S-□ is short nose type.

(there is no stopper in the sleeve so that tool can be installed from the front side.)

8, Inner coolant is not compatible with this series.

-

Collet holder for OH (Sleeve)

Collet holder used in combination with a coolant collet.

There is an internal thread for piping either at the end of the holder or on the side face.

Specification・Size

| CODE (FIG 1) | d | D | L | L1 | L2 | max L3 | C1 | L4 | W | Option | |

| Collet | Wrench | ||||||||||

| SSH20-ECH 7OH- 70 | 3~7 | 20 | 70 | 106 | 36 | 55 | 23 | 11.5 | 27 | AR11OH-d | FK-3 |

| SSH20-ECH10OH- 40 | 3~10 | 40 | 85 | 45 | 45 | 32 | 17 | 30 | AR16OH-d | FK-4 | |

| SSH20-ECH10OH- 70 | 70 | 115 | 70 | ||||||||

| SSH20-ECH13OH- 70 | 5~3 | 117.5 | 47.5 | 75 | 36 | 19 | 32 | AR20OH-d | FK-5 | ||

| SSH25-ECH10OH- 70 | 3~10 | 25 | 70 | 115 | 45 | 70 | 32 | 17 | 30 | AR16OH-d | FK-4 |

| SSH25-ECH10OH-105 | 105 | 150 | 80 | ||||||||

| SSH25-ECH13OH- 70 | 5~13 | 70 | 117.5 | 47.5 | 75 | 36 | 19 | 32 | AR20OH-d | FK-5 | |

| SSH25-ECH16OH- 70 | 6~16 | 121 | 51 | 80 | 43 | 20 | 36 | AR25OH-d | FK-6 | ||

| SSH32-ECH13OH- 75 | 5~13 | 32 | 75 | 122.5 | 47.5 | 75 | 36 | 19 | 32 | AR20OH-d | FK-5 |

| SSH32-ECH16OH- 75 | 6~16 | 126 | 51 | 80 | 43 | 20 | 36 | AR25OH-d | FK-6 | ||

| SSH32-ECH20OH- 75 | 8~20 | 130 | 55 | 51 | 23 | 46 | AR32OH-d | FK-8 | |||

| SSH3/4-ECH10OH-105 | 3~10 | 19.05 | 105 | 150 | 45 | 32 | 17 | 30 | AR16OH-d | FK-4 | |

| SSH 1 -ECH10OH-105 | 25.4 | ||||||||||

| CODE (FIG 2) | d | D | L | L1 | L2 | L3 | C1 | L4 | W | Option | |

| Collet | Wrench | ||||||||||

| SSH20-ECH 7S OH- 40 | 3~7 | 20 | 40 | 56 | 16 | 31 | 19 | 11.5 | 17 | AR11OH-d | SP-17A |

| SSH20-ECH10S OH- 40 | 3~10 | 62 | 22 | 33 | 28 | 17 | AR16OH-d | SP-25 | |||

| SSH20-ECH10S OH- 70 | 70 | 92 | 55 | ||||||||

| SSH25-ECH10S OH- 40 | 3~10 | 25 | 40 | 63 | 23 | 33 | 22 | ||||

| SSH25-ECH10S OH- 50 | 50 | 73 | |||||||||

| SSH25-ECH13S OH- 50 | 5~13 | 73.5 | 23.5 | 40 | 34 | 19 | AR20OH-d | SP-30 | |||

| SSH32-ECH20S OH- 80 | 8~20 | 32 | 80 | 115 | 35 | 75 | 50 | 23 | 36 | AR32OH-d | FK-7 |

Notice

1, The holder is used in combination with a coolant collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, We offer special shank size which is not shown on the above table as well.

4, ECH20S is used in combination with different type of nuts.

-

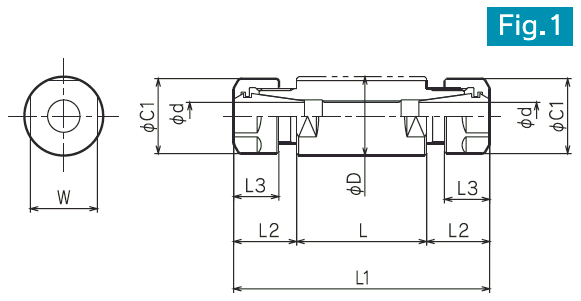

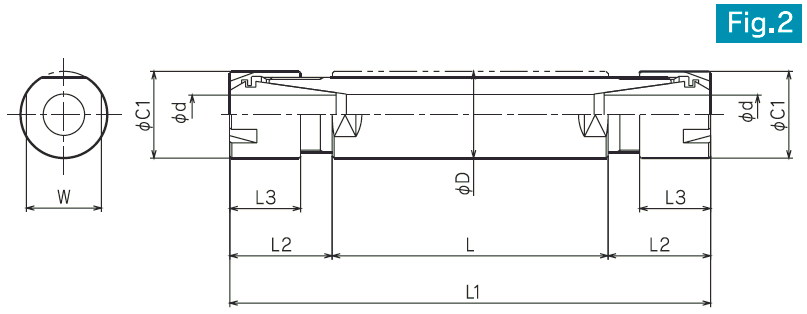

Double-headed collet holder

This holder can hold two collets with each end at the same time and is able to process face milling.

| CODE | d | D | FIG | L | L1 | L2 | Nut | W | Option | |||

| C1 | L4 | Collet Chuck | Wrench | |||||||||

| ◯ | SSH20-ECH 7WS- 33 | 0.5~7 | 20 | 1 | 33 | 65 | 16 | 19 | 11.5 | 17 | AR11-d | SP-17A |

| ◯ | SSH20-ECH 7WS- 53 | 53 | 85 | |||||||||

| SSH3/4-ECH 7WS- 33 | 19.05 | 33 | 65 | |||||||||

| ◯ | SSH3/4-ECH 7WS- 53 | 53 | 85 | |||||||||

| SSH22-ECH10WM- 38 | 0.5~10 | 22 | 2 | 38 | 90 | 26 | 22 | 18 | 19 | AR16-d | AE-16M | |

| SSH22-ECH10WM- 63 | 63 | 115 | ||||||||||

| ◯ | SSH22-ECH10WM- 70 | 70 | 122 | |||||||||

| ◯ | SSH22-ECH10WM- 85 | 85 | 137 | |||||||||

| SSH22-ECH10/7WSMS-100 | 0.5~7 | 3 | 100 | 142.5 | 16.5 | 19 | 11.5 | AR11-d | SP-17A | |||

| 0.5~10 | 26 | 22 | 18 | AR16-d | AE-16M | |||||||

| SSH25-ECH10WM- 50 | 0.5~10 | 25 | 2 | 50 | 102 | – | ||||||

| SSH25-ECH13/10WM- 50 | 1~13 | 3 | 103 | 27 | 28 | 19 | 22 | AR20-d | AE-20M | |||

| 0.5~10 | 26 | 22 | 18 | AR16-d | AE-16M | |||||||

| SSH 1 -ECH10WM- 70 | 0.5~10 | 25.4 | 2 | 70 | 122 | 26 | 22 | 18 | 22 | AR16-d | AE-16M | |

| SSH 1 -ECH10WM-105 | 0.5~10 | 105 | 157 | |||||||||

| SSH 1 -ECH13/10WM- 70 | 1~13 | 3 | 70 | 123 | 27 | 28 | 19 | AR20-d | AE-20M | |||

| 0.5~10 | 26 | 22 | 18 | AR16-d | AE-16M | |||||||

| SSH 1 -ECH13/10WM-105 | 1~13 | 105 | 158 | 27 | 28 | 19 | AR20-d | AE-20M | ||||

| 0.5~10 | 26 | 22 | 18 | AR16-d | AE-16M | |||||||

| SSH32-ECH13WM- 55 | 1~13 | 32 | 2 | 55 | 109 | 27 | 28 | 19 | 27 | AR20-d | AE-20M | |

| SSH32-ECH13WM- 85 | 85 | 139 | ||||||||||

Notice

1, Holders are used in combination with chuck collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, Products with ○ at CODE column are standard stock.

4, We will produce special shank in size not shown in the above tables.

-

Double-headed tap holder

This holder can hold two collets with each end at the same time and is able to process face milling.

| CODE | d | D | FIG | L | L1 | L2 | L3 | Nut | W | X | Option | |||

| C1 | L4 | Collet | Wrench | |||||||||||

| ◯ | SST22-ECH10WM- 50 | ~M12 | 22 | 1 | 50 | 111 | 30.5 | – | 22 | 18 | 19 | 6 | AR16-d | AE-16M |

| SST22-ECH10WM- 80 | 80 | 142 | 31 | 39.5 | 10 | |||||||||

| SST32-ECH10WS- 65 | 32 | 2 | 65 | 124 | 29.5 | 39 | 28 | 17 | 27 | SP-25 | ||||

Notice

1, Holders are used in combination with chuck collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, Products with ○ at CODE column are standard stock.

4, We will produce special shank in size not shown in the above tables.

-

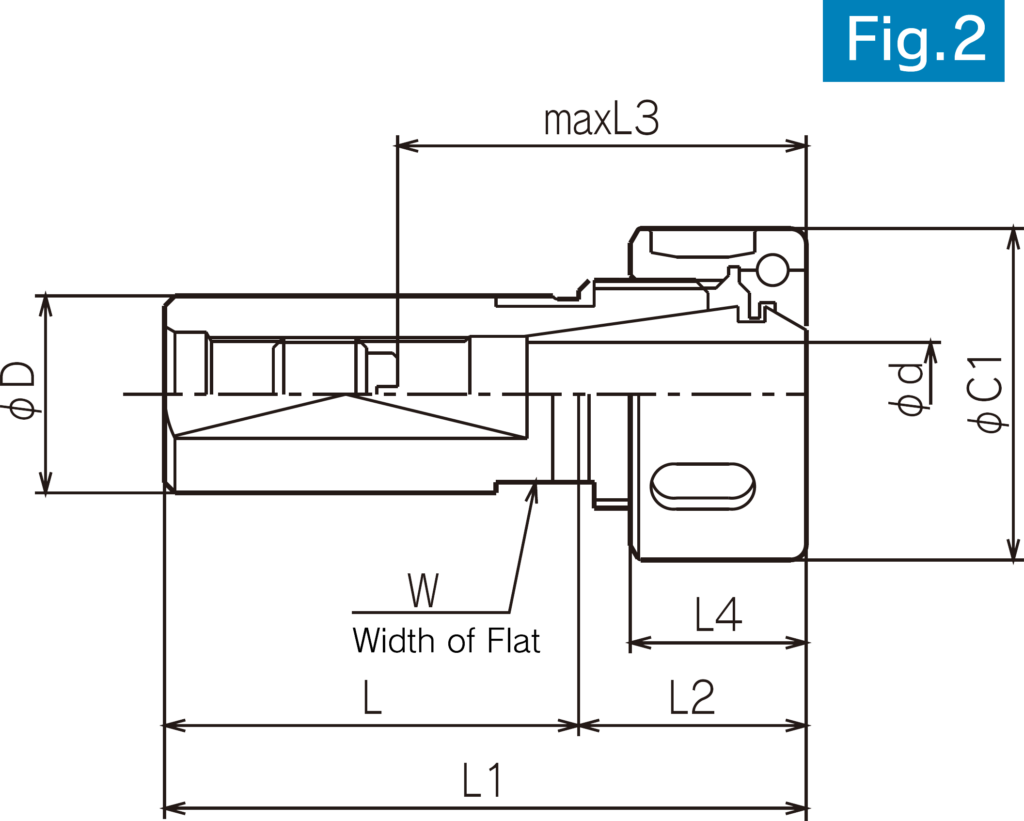

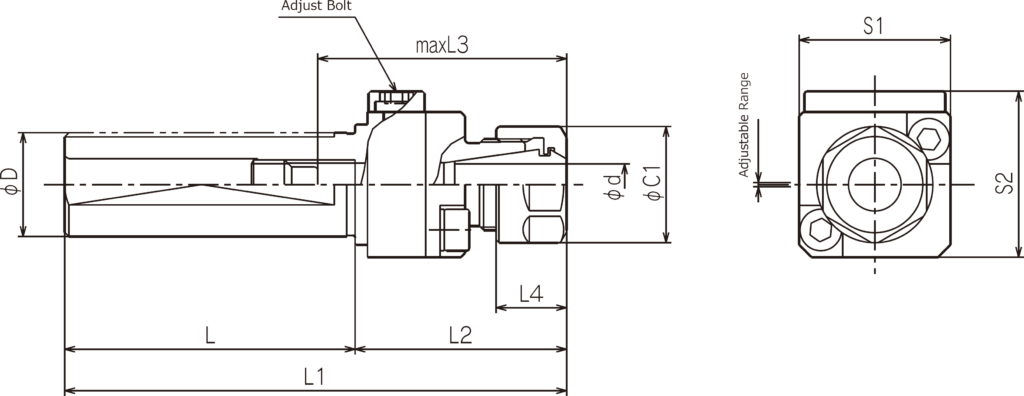

Core height adjusting collet holder

This holder is capable of correcting misalignment of core height between the main spindle and cutter rest of lathes.

・Core height can be adjusted in 0.6 mm (±0.3 mm) of adjustable range.

・The holder help prolonging tool life including carbide drills and reamers.

・The holder can compensate the accuracy deterioration of a cutter rest.

Specification Size

| CODE | D1 | D2 | L | L1 | L2 | max L3 | S1 | S2 | Nut | Option | ||||

| L4 | C1 | Collet | Wrench | Adjust Bolt Wrench | ||||||||||

| SBH3/4-ECH 7M- 70 | 0.5~7 | 19.05 | 70 | 108 | 38 | 55 | 25 | 29 | 12 | 16 | AR11-d | AE-11M | H3 | |

| SBH20-ECH 7M- 70 | 20 | |||||||||||||

| ◯ | SBH20-ECH10 – 70 | 0.5~10 | 121 | 51 | 60 | 36.5 | 40 | 17 | 28 | AR16-d | SP-25 | H5 | ||

| ◯ | SBH25-ECH10 – 70 | 25 | ||||||||||||

| SBH25-ECH16 – 70 | 1~16 | 125 | 55 | 70 | 47 | 49 | 20 | 42 | AR25-d | FK-6 | ||||

| SBH32-ECH16 – 70 | 1~16 | 32 | ||||||||||||

| SBH32-ECH20 – 70 | 1~20 | 133 | 63 | 59 | 60 | 23 | 50 | AR32-d | FK-8 | H6 | ||||

Notice

1, Holders are used in combination with chuck collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, Products with ○ at CODE column are standard stock.

4, We will produce special shank in size not shown in the above tables.

-

Core adjusting collet holder

This holder is capable of correcting misalignment of core between the chuck and the turret of lathes.

・Core height can be adjusted in 0.1 mm of adjustable range.

・The holder realizes highly precise machining and help prolonging tool life including carbide drills and reamers.

・The holder can compensate the accuracy deterioration of a cutter rest.

Specification・Size

| CODE | d | D | L | L1 | L2 | max L3 | D1 | Nut | Option | |||||

| L4 | C1 | Collet | Wrench | Lock Bolt Wrench | Adjust Bolt Wrench | |||||||||

| SAH20-ECH 7- 70 | 0.5~7 | 20 | 70 | 105 | 35 | 55 | 32 | 11.5 | 19 | AR11-d | SP-17A | H4 | H2.5 | |

| ◯ | SAH20-ECH10- 70 | 0.5~10 | 114 | 44 | 60 | 50 | 17 | 32 | AR16-d | FK-4 | ||||

| ◯ | SAH25-ECH10- 70 | 25 | ||||||||||||

| SAH25-ECH16- 70 | 1~16 | 124 | 54 | 70 | 62 | 20 | 43 | AR25-d | FK-6 | H5 | H3 | |||

| SAH32-ECH13- 70 | 1~13 | 32 | 119 | 49 | 55 | 19 | 36 | AR20-d | FK-5 | |||||

| SAH32-ECH20- 70 | 2~20 | 126 | 56 | 72 | 23 | 51 | AR32-d | FK-8 | ||||||

Notice

1, Holders are used in combination with chuck collet, please order it separately.

2, A spanner is not supplied, please order it separately.

3, Products with ○ at CODE column are standard stock.

4, We will produce special shank in size not shown in the above tables.